TM 5-3895-373-20

2.24.3. SCREED REMOVAL AND INSTALLATION.

This task covers:

a. Remove

b. Install

INITIAL SETUP

Tools:

General mechanic’s automotive tool kit

(Item 54, Appendix E)

Crowbars, 2 ea (Item 11, Appendix E)

Drip pan (Item 28, Appendix E)

High pressure caps, 2 ea (Item 8, Appendix E)

Screwdriver bit set (Item 37, Appendix E)

Torque wrench (Item 68, Appendix E)

Materials/Parts:

Cleaning cloth (Item 7, Appendix C)

Electrical insulating compound (Item 11, Appendix C)

Hydraulic fitting sealant (Item 21, Appendix C)

Lint-free cloth (Item 8, Appendix C)

Machinery wiping towel (Item 30, Appendix C)

Tags (Item 27, Appendix C)

Thread locking compound (Item 12, Appendix C)

Thread locking compound solvent (Item 25, Appendix C)

Tie wraps (Item 29, Appendix C)

Protective caps (Item 5, Appendix C)

Personnel Required:

Three 62B construction equipment repairers. Additional

persons needed to hold drip pan, to help remove and

install screed lift clevis pins, and to act as spotters for

driving tractor away from and toward screed.

References:

TM 5-3895-373-10

Equipment Condition:

Screed lowered onto level concrete or asphalt surface

per

TM 5-3895-373-10.

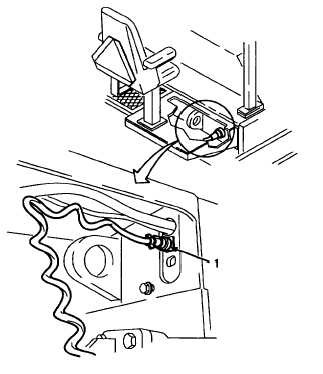

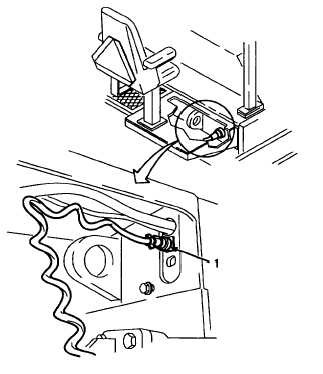

NOTE

Disconnection procedure for left hand and right hand

feed limit switch harness connectors is the same. Right

hand feed limit switch harness connector is shown in this

procedure.

A.

REMOVE.

1. UNPLUG SCREED HARNESS CONNECTORS.

a.

Unscrew and unplug feed limit switch harness

connectors (1) from left and right hand sides of

tractor bulkhead.

GO TO NEXT PAGE

2-455