TM 5-3895-373-20

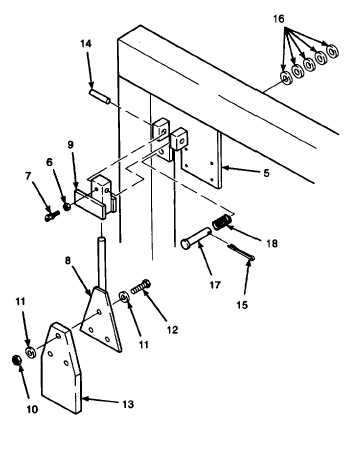

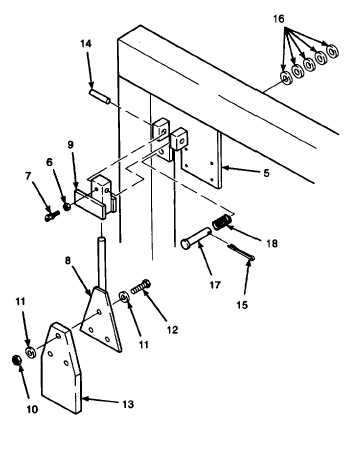

15.17. REPLACE/REPAIR FEED LIMIT SWITCH PADDLE ASSEMBLY - Continued.

C.

INSTALL Continued.

2.

INSTALL FEED LIMIT SWITCH PADDLE

CONTROL ARM.

a.

Position actuator mount (9) onto endgate

support arm (5) and secure with spring pins (14).

b.

Place control arm rubber extension (13) on feed

limit switch paddle (8) and secure with hex head

cap screws (12), flat washers (11) and self-

locking nuts (10). Tighten to 108 lb-in (12 N•m).

c.

Place hex nut (6) onto thumbscrew (7) and

install into actuator mount (9).

d.

Install spring (18) onto straight headed pin (17)

and install into endgate support arm (5).

NOTE

Flat washers are installed on straight

headed pin (17) in front or back of

endgate support arm (5). Washers are

installed on pin to adjust pin length to

prevent paddle assembly from actuating

feed limit switch with no paving material

present.

e.

Observe contact on arm of actuator mount (9).

Add flat washers (16), as required, between

spring (18) and endgate support arm (5), to

allow arm of actuator mount to touch the head

of straight headed pin (17) and actuate feed

limit switch with no compression of spring.

f.

Install flat washers (16) as required on back of

straight headed pin (17) behind endgate support

arm (5) to fill space between support arm and

cotter pin hole. Install cotter pin (15).

g.

Insert feed limit switch paddle (8) into actuator

mount (9). Tighten thumbscrew (7) and snug

hex nut (6).

NOTE

FOLLOW-ON-TASK: Install endgate hand lever assembly per paragraph 15.16.

END OF TASK

15-124