TM 5-3895-373-10

2.14

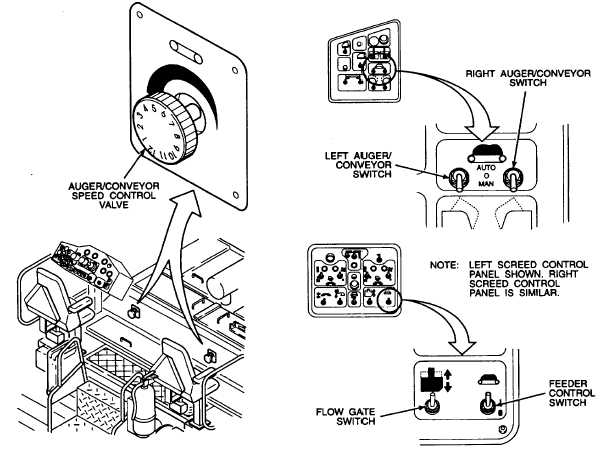

AUGER/CONVEYOR OPERATIONS.

The auger/conveyor system is a dual system. There are

left and right controls to operate each system together,

independently, and in different modes, if required. The

following operating instructions discuss operating the

system as a dual system. To operate the left or right

side independently use the left or right side controls

separately.

2.14.1

Manual Operation.

a.

Turn left and right auger/conveyor speed control

valves fully clockwise and then back-off each

valve three clicks. This is done to balance out

auger/conveyor speed at the start of paving. To

further

adjust

the

speed

of

left

or

right

auger/conveyor systems, turn the speed control

valve counterclockwise to increase speed and

clockwise to decrease speed.

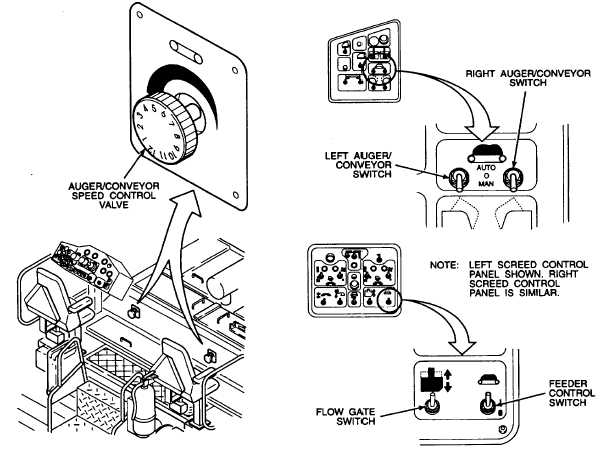

b.

Place left and right auger/conveyor switches to

MAN.

NOTE

Either left or right feeder control

switches and left or right flow gate

switches can be used to regulate flow

of paving material from the hopper to

the augers. The two controls can be

used independently or together to

maintain the desired level of paving

material in auger chamber. These

switches are located on both left and

right

screed

control

panels

and

operator

control

console

switch

panel.

c.

Move the flow gate switch up to increase the

material flow or down to decrease or stop the

material flow. The flow gate switch is used to

maintain proper paving material level in the

auger chamber. Depth of paving material should

be maintained at one half to three quarters the

height of the auger diameter.

2-38