TM 5-3895-373-10

b.

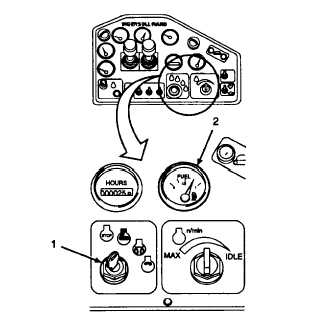

Turn ignition switch (1) to ON position and check

fuel gauge (2) for the amount of fuel in the fuel

tank.

c.

Open left access door per paragraph 2.24.1.

d.

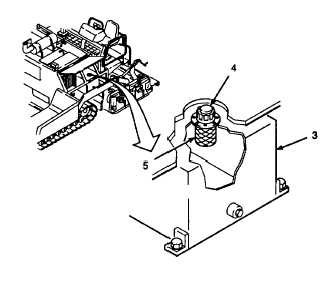

Use a cleaning cloth (Item 1, Appendix D) and

wipe dirt and any foreign material from area on

top of fuel tank (3) around fuel tank cap (4).

e.

Unscrew fuel tank cap (4) and set cap aside.

Fuel is very flammable and can explode

easily.

To avoid serious injury or death: Always

wear safety glasses/goggles at all times.

Keep fuel away from open flame or any spark

(ignition source).

Keep at least a B-C fire extinguisher within

easy reach when working with fuel or on a

fuel system.

Do not work on fuel system when engine is

hot; fuel can be ignited by a hot engine.

Clean fuel tank to purge any flammable liquid

or vapors before welding, grinding, or using

any heat producing device near the fuel tank.

Post signs that read "NO SMOKING WITHIN

50 FEET" when working with open fuel lines

or fuel tanks.

CAUTION

Do not overfill fuel tank. When diesel fuel in

fuel tank begins to foam up into filler neck

the tank is full. Spilled fuel may accumulate

in hard to reach areas inside paving machine

engine compartment and cause a fire hazard.

Wipe up any spilled fuel immediately after

refueling. Dispose of contaminated rags in

accordance with local procedures.

f.

Check for any foreign material accumulated in

filler neck strainer (5). Notify Unit Maintenance if

any foreign material is observed.

g.

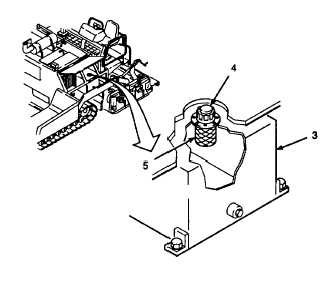

Place fuel nozzle into filler neck and begin

adding diesel fuel (Item 4, Appendix D).

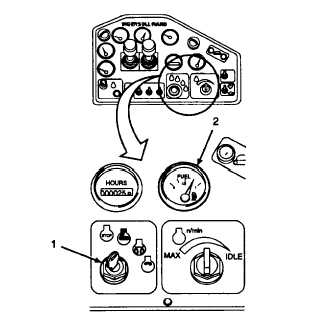

Periodically stop fueling and check fuel gauge

for level of fuel in tank. Fuel tank is full when

gauge needle points to "1" increment mark. Do

not overfill the fuel tank; stop fueling when fuel in

tank starts to foam up into filler neck.

h.

Turn ignition switch (1) to stop position and

remove ignition key.

3-21