TM 5-3895-356-14&P

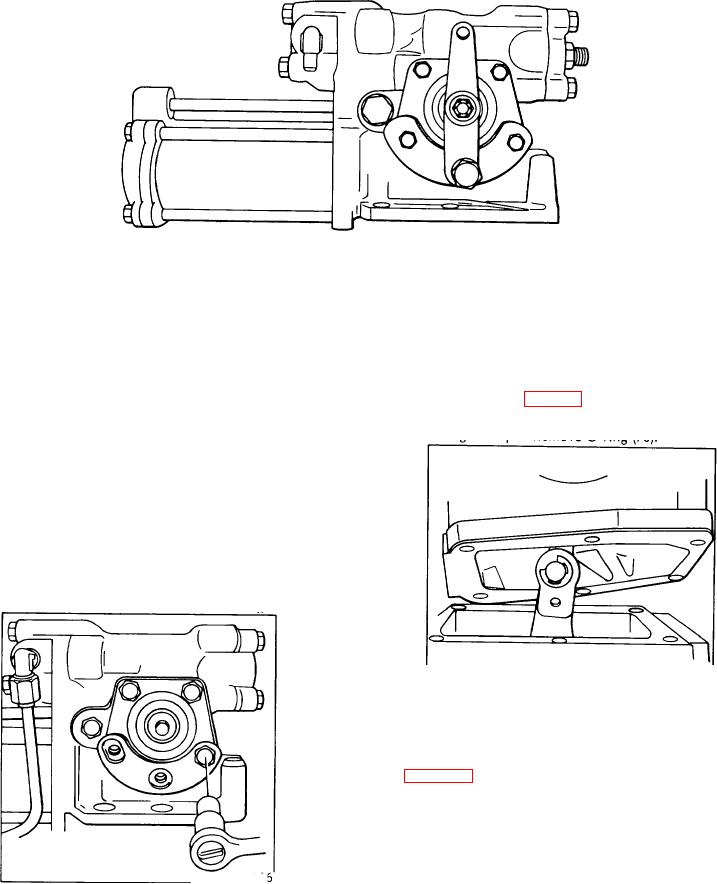

OVERHAUL - LONG DIFFERENTIAL PRESSURE

COMPENSATED OVERRIDE CONTROL

Figure 165.

The following procedure details the removal and

2.

overhaul of the standard horsepower control with

Remove six bolts (4 short, 2 long)

adjustable neutral detent.

items (28) & (38), and six lock washers (63).

This procedure is also applicable to the low pressure

3. Lift control assembly from pump housing, breaking

servo control and the short differential pressure

the seal with gasket (65). Care should be taken to avoid

compensated override control. When servicing either of

bending the feedback lever (22) by swinging it to one

these control types, omit the appropriate steps where

side, as illustrated in Fig.167 before proceeding to Step

indicated.

4. Remove O-ring (70).

ALL PART NUMBERS IN PARENTHESIS FOLLOWING

THE PART NAMES REFER TO TO THE INDIVIDUAL

PARTS AS IDENTIFIED IN FIGURE 238 EXCEPT AS

NOTE D.

CONTROL DISASSEMBLY

1.

Remove lock

nut (41), washer (40) and lever assembly (82)

Remove

two cap screws (76),

two lock

washers (25)

Fig. 166.

Figure 167.

Cam actuator arm and valve sleeve

4. With a small screwdriver, remove E-ring (71) from

the side of the cam arm opposite the counterbore. A

clean shop rag should be positioned around the cam arm

to prevent the loss of the E-ring into the pump housing.

See Fig. 168.

5. Remove clevis pin (73) with 2nd E-ring and slip the

control link (72) from the cam lever. Remove gasket

(65) from control housing.

6. Remove two cap screws (74) and two lock washers

(25). Slip seal plate assembly (42) off over control valve

Figure 166.

(23).

Fig. 166. Removing adjustable neutral detent

106