TM 5-3895-356-14&P

5. Install housing cover (26) with four cap screws (24),

lock washers (25), and a new gasket (27). If one cap

screw (24) was prepared with tape in Step 4, be certain it

is positioned at the end of the cam follower pivot through

hole). See Fig. 176. Torque cap screws to 132 in. lbs.

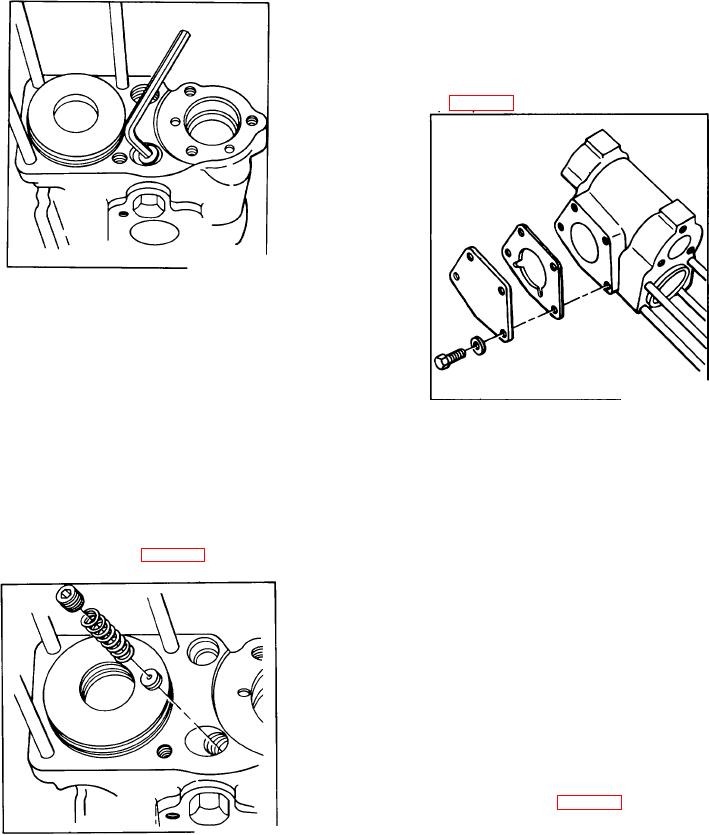

Figure 174.

Removing orifice

During reassembly, check all moving parts for smooth

operation. It is essential that there be no binding or

interference between any internal moving parts.

This procedure is also applicable to the low pressure

servo control and the short differential, pressure

Figure 176.

compensated override control. When servicing either of

Control housing cover

these control types, omit the appropriate steps where

indicated.

6. If removed during disassembly, inspect four studs

(15) for damaged threads, bends, twists or cracks and

1. Inspect servo rod bushing (68).

replace if necessary. Use Loctite sealant, Grade 3, on

coarse threaded end of studs and install in housing (57).

2. If removed during disassembly, install orifice (53)

Torque studs down tight.

and spring (52) with plug (51) using Loctite pipe sealant.

Torque plug down tight. See Fig. 175

7. Inspect piston (45) for nicks or scratches around the

perimeter. If observed, replace piston (45). Inspect link

end of rod assembly (67) for cracks. Replace rod

assembly (67) if cracks are found. Install piston (45) on

rod assembly (67) with washer (66) and selflocking nut

(44). Torque selflocking nut (44) to 420 in. lbs.

8. Install three new O-rings (46) on housing (57), piston

(45), and cylinder cover (43). Install servo plunger

assembly in control housing (57).

9. Lubricate the entire inner surface of cylinder tube

(16) with clean transmission oil. Install cylinder tube (16)

over servo piston assembly (45) and seat tube (16)

against housing (57). See Fig. 177.

10. Install two new O-rings (14) on each end of transfer

Figure 175.

tube (17). Lubricate the ends of the transfer tube (17)

Plug, spring & orifice

and insert in cylinder cover (43). Install cylinder cover

NOTE:

(43) with new O-ring (46) and transfer tube over studs

Omit Step 3 and 4 if servicing a Low

(15) and seat into end of servo

Pressure Servo Control.

Omit Step 3 if servicing a Short

Differential Pressure Compensated

Override Control.

109