TM 5-3895-356-14&P

500 R P.M. input equals 204 gal/min. For example, with

D. Manual Control

a 600 R P M input speed, again from an electric drill

press or other source, the pump flow indicator should

Place distributor control lever in "Fill from supply

read 244 gal/min. (600/500 X 204 = 244). Replace

source" position (Fig. 69). Engage P T.O., set micro

indicators as necessary.

control to 100 G P M. flow, open supply source valve

and draw into the distributor approximately 100 gallons of

testing oil (Relatively clean used engine oil of SAE grade

B. Final Inspection

40 would be satisfactory) Close supply source valve,

Check oil level in hydraulic reservoir and add if

reduce pump flow to zero and disconnect fill hose at

necessary With distributor circulating in tank at 200 G

distributor Replace fill line cap and locate distributor

P.M., and hydraulic oil at operating temperature, check to

levers and spray bar ends for circulate in bar position

insure suction on filter is not in red zone. If suction

(Figure 33) Engage P T O and set micro control to 100

indicates in red zone, replace filter element Place

G.P M At this time, check for leaks m spray bar and lines

distributor control levers m "draw back" position (Fig. 71

from asphalt pump. Tighten fittings and valves where

) to draw all material back into tank Pump test oil back

necessary. Note, a small amount of leakage may occur

into supply source as instructed in Fig. 73 for "pump off"

from ball joints until hot asphaltic material has circulated

procedure Open dram valves after pump-off by placing

through spray bar After eliminating leaks, place

drain valve lever m rear most position This will remove

distributor control levers in draw-back position (Fig. 71 )

most residual test oil from distributor system. Finally,

so as to draw all oil back into the tank

drain burner fuel from supply tank by opening petcock on

bottom of tank

III. DRY RUN CHECK OUT

A. Operation of Distributor Controls

First with bar turned up and ends latched in place,

move distributor levers to circulate in tank position (Fig.

72). Next, let fifth wheel down and with P T.O. engaged

drive distributor forward at a steady speed of 300 ft/min.

While driving at this steady speed, adjust micro control

until pump flow rate is 100 gal/min Hold micro control in

this location by turning lock tube up against under side of

micro control knob After locking knob in place, increase

distributor ground speed to 450 ft/min Pump flow rate

should be 150 gal/min. Next, decrease speed to 200

ft/min and flow rate should drop to 75 gal/min. If these

ground speeds and flow rates do not correspond, check

for air leaks in suction line between hydraulic reservoir

and pump suction port Tighten fittings as necessary Air

in hydraulic oil will cause it to appear milky If this is not a

problem, check ground speed indicator dial, 1000 R P M.

input equals 1000 FPM reading Therefore, if R P.M. of

say an electric drill press, for example, is known to be

600 R P M., then the ground speed indicator should read

600 ft/mm. when driven by the drill press. If ground

speed indicator, (bitumeter) checks satisfactory proceed

to check pump flow indicator.

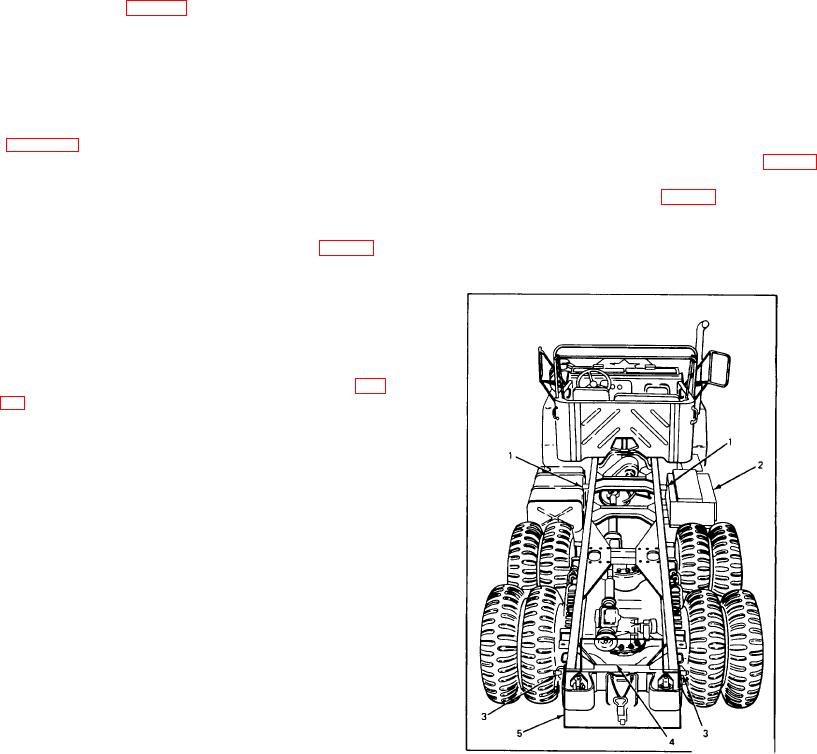

Figure 38

Chassis Components to be Removed

1. Left and Right Tie Down

4. Wiring Harness

2. Tool Box

5. Rear Cross Member

3. Glad Hands

36