130F with any of these light weight or diluted oils.

2. Antiwear Type Hydraulic Oil - There is no common

designation for oils of this type. However, they are

produced by all major oil suppliers and provide the

OTHER FACTORS IN SELECTING AN OIL ARE:

antiwear qualities of MS crankcase oils.

1. Viscosity - Viscosity is the measure of fluidity. In

addition to dynamic lubricating properties, oil must have

3. Certain Other Types Of Petroleum Oils are suitable

sufficient body to provide adequate sealing effect between

for Mobile hydraulic service if they meet the following

working parts of pumps, valves, cylinders and motors, but

provisions:

not enough to cause pump cavitation or sluggish valve

(a) Contain the type and content of antiwear

action. Optimum operating viscosity of the oil should be

impounding found in MS crankcase oils or have passed

between 80 SSU and 180 SSU. During sustained high

pump tests similar to those used in developing the antiwear

temperature operation viscosity should not fall below 60

type hydraulic oils.

SSU.

(b) Meet the viscosity recommendations shown in

the following table.

2. Viscosity Index - Viscosity index reflects the way

(c) Have sufficient chemical stability for Mobile

viscosity changes with temperature. The smaller the

hydraulic system service.

viscosity change the higher the viscosityindex.

The

viscosity index of hydraulic system oil should not be less

The following types of oil are suitable if they meet the

than 90. Multiple viscosity oils, such as SAE 10W-30,

above three provisions:

incorporate additives to improve viscosity index (polymer

thickened).

Oils of this type generally exhibit both

Series 3 Diesel Engine Oil

temporary and permanent decrease in viscosity due to the

Automatic Transmission Fluid Types A, F and DEXRON

oil shear encountered in the operating hydraulic system.

Hydraulic Transmission Fluid Types C-1 and C-2

Accordingly, when such oils are selected, it is desirable to

use those with high shear stability to insure that viscosity

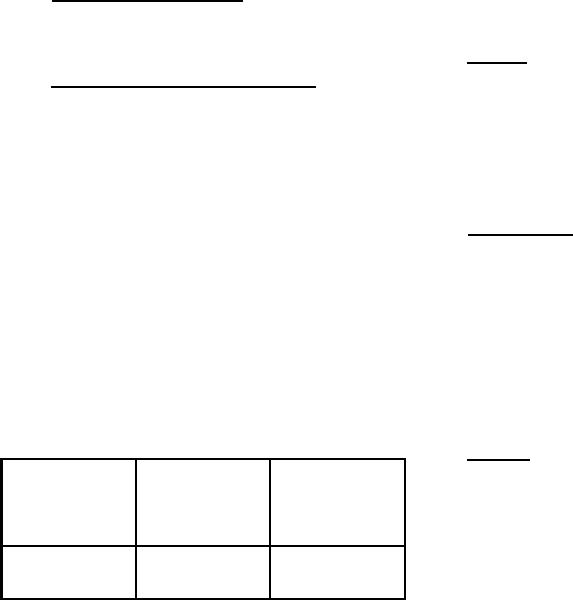

The

following

table

summarizes

oil

types

remains within recommended limits.

recommended for use with Vickers equipment in Mobile

hydraulic systems by viscosity and service classification.

3. Additives - Research has developed a number of

American

Hydraulic System

additive agents which materially improve various

Petroleum

Operating

characteristics of oil for hydraulic systems.

These

Institute (API)

Temperature

SAE Viscosity

additives are selected to reduce wear, increase chemical

Service

Range

Designation

stability, inhibit corrosion and depress the pour point. The

Classification

(Min. * to Max.)

most desirable oils for hydraulic service contain higher

0F to 180F

10W

MS

amounts of antiwear compounding.

0F to 210F

10W-30**

MS

50F to 2100F

20-20W

MS

SPECIAL REQUIREMENTS

* Ambient Start Up Temperature

Where special considerations indicate a need to depart

** See paragraph on Viscosity Index

from the recommended oils or operating conditions, see

your Vickers sales representative.

OPERATING TEMPERATURE

CLEANLINESS

The temperatures shown in table are cold start-up to

Thorough precautions should always be observed to

maximum operating. Suitable start-up procedures must be

insure that the hydraulic system is clean:

followed to insure adequate lubrication during system

warm-up.

1. Clean (flush) entire system to remove paint, metal

chips, welding shot, etc.

ARCTIC CONDITIONS

2. Filter each change of oil to prevent introduction of

contaminant into the system.

Arctic conditions represent a specialized field where

extensive use is made of heating equipment before

3. Provide continuous oil filtration to remove sludge

starting. If necessary, this, and judicious use of SAE 5W or

and products of wear and corrosion generated during the

SAE 5W-20 oil in line with the viscosity guide lines shown

life of the system.

in the table, may be used. Dilution of SAE 10W (SM) oil

4. Provide continuous protection of system from entry

with maximum of 20% by volume of kerosene or low

of airborne contamination.

temperature diesel fuel is permissible. During cold start-

up, avoid high speed operation of hydraulic system

5. During usage, proper oil filling and servicing of

components until the system is warmed up to provide

filters, breathers, reservoirs, etc., cannot be over-

adequate lubrication. Operating temperature should be

emphasized.

closely monitored to avoid exceeding a temperature of

7