Section II - DESCRIPTION

As the rotor is driven by the driveshaft, the vanes generate

A. GENERAL

fluid flow by carrying fluid around the elliptical ring contour

(see section m). Fluid enters the cartridge through the

Pumps in this series are used to develop hydraulic fluid

inlet port in the body and is discharged through the

flow for the operation of Mobile equipment. The positive

pressure plate to the outlet port in the cover.

displacement pumping cartridges are the rotary vane type

with shaft side loads hydraulically balanced. The flow rate

depends on the pump size and the speed at which it is

C. FLOW CONTROL AND RELIEF VALVE

driven.

V200 pumps are available with an integr Flow Control

All units are designed so that the direction of rotation,

and Relief Valve in the pump cover. This limits the fluid

pumping capacity and port positions can be readily

flow in the system to a maximum prescribed rate and

changed to suit particular applications.

prevents excessive pressure build-up. Fluid not required

in the system is recirculated to tank.

B. ASSEMBLY AND CONSTRUCTION

D. APPLICATION

The V200 series pump illustrated in cutaway in Figure

1 is representative of all single pumps in this series. The

Pump ratings in GPM as shown in the model coding are at

unit consists principally of a ported body and cover, a drive

1200 RPM.

For ratings at other speeds, methods of

installation and other application information, Vickers

shaft supported by two ball bearings, a pumping cartridge

Mobile Division Application engineering personnel should

and a pressure plate. The components of the cartridge are

be consulted.

an elliptical ring, a slotted rotor splined to the drive shaft

and twelve vanes fitted to the rotor slots.

Section III - PRINCIPLES OF OPERATION

Radial movement of the vanes and turning of the rotor

A. PUMPING CARTRIDGE

cause the chamber between the vanes to increase as the

vanes pass the inlet sections of the ring. This results in a

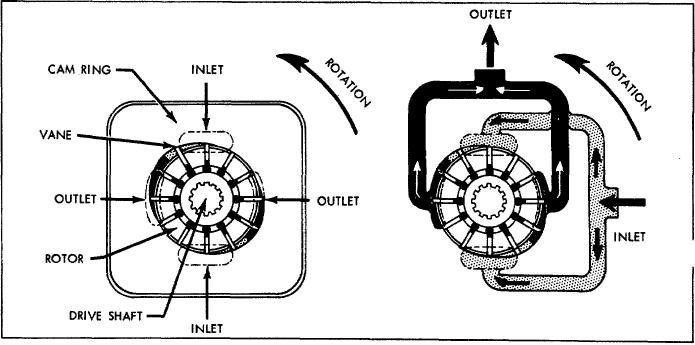

As mentioned in Section II;, fluid flow is developed in

low pressure condition which allows atmospheric pressure

the pumping cartridge. The action of the cartridge is

to force fluid into the chambers. (Fluid outside the inlet is

illustrated in Figure 2. The rotor is driven within the ring by

at atmospheric pressure or higher.)

the driveshaft, which is coupled to a power source.

As

the rotor turns, centrifugal force on the vanes causes them

to follow the elliptical inner surface of the ring.

Figure 2

4