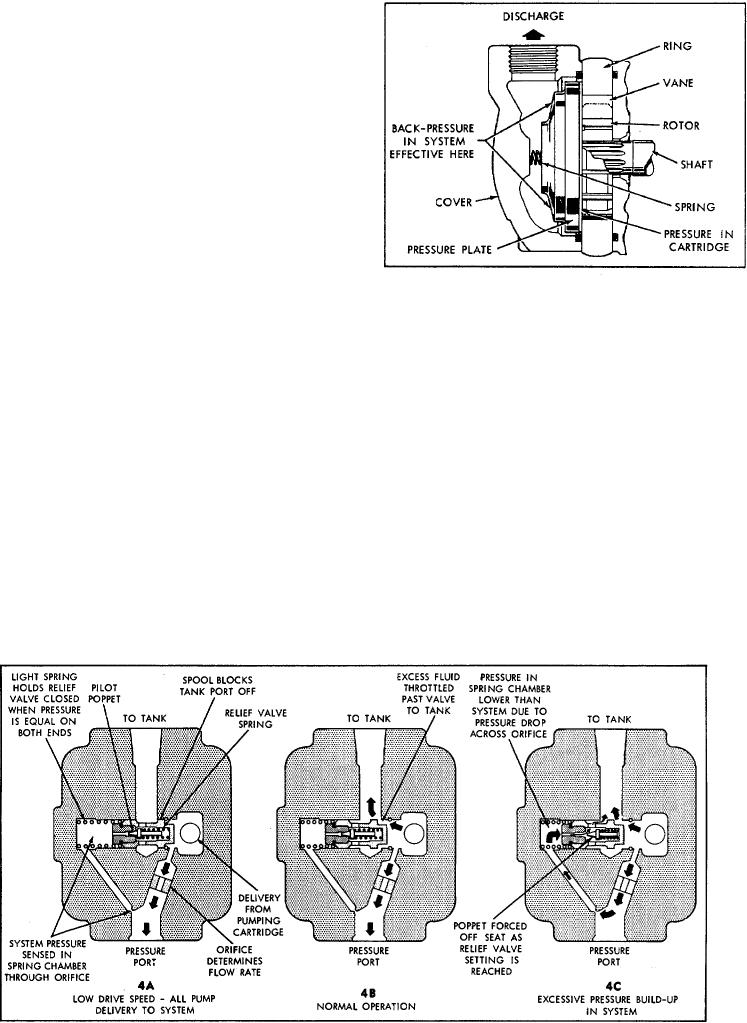

This fluid is trapped between the vanes and carried past

the large diameter or dwell section of the ring. As the

outlet section is approached, the ring diameter decreases

and the fluid is forced out into the system. System

pressure is fed under the vanes, assuring their sealing

contact against the ring during normal operation.

B. HYDRAULIC BALANCE

The pump ring is shaped so that the two pumping

chambers are formed diametrically opposed.

Thus,

hydraulic forces which would impose side loads on the

shaft cancel each other out.

C. PRESSURE PLATE

The pressure plate seals the pumping chamber as shown in

Figure 3

Figure 3.

A light spring holds the plate against the

cartridge until pressure builds up in the system. System

This condition usually occurs only at low drive speeds.

pressure is effective against the area at the back of the

The large spring chamber is connected to the pressure

plate, which is larger than the area exposed to the pumping

port through an orifice. Pressure in this chamber equalizes

cartridge. Thus, an unbalanced force holds the plate

pressure at the other end of the relief valve spool and the

against the cartridge, sealing the cartridge and providing

light spring holds the spool closed.

Pump delivery is

the proper running clearance for the rotor and vanes.

blocked from the tank port by the spool land.

D. FLOW CONTROL AND RELIEF VALVE

3. When pump delivery is more than the flow rate

determined by the orifice plug, a pressure build-up forces

1. Maximum pump delivery and maximum system

the spool open against the light spring.

Excess fluid is

pressure are determined by the integral flow control and

throttled past the spool to the tank port as shown in Figure

'relief valve in a special outlet cover used on some V200

4B.

pumps. This feature is illustrated schematically in Figure

4. An orifice in the cover limits maximum flow. A pilot-

4. If pressure in the system builds up to the relief

operated type relief valve shifts to divert excess fluid de-

valve setting (Figure 4C), the pilot poppet is forced off its

livery to tank, thus limiting the system pressure to a

seat. Fluid in the large spring chamber flows through the

prescribed maximum.

spool and out to tank.

This flow causes a pressure

differential on the spool, shifting it against the light spring.

2. Figure 4A shows the condition when the total pump

All pump delivery is thus permitted to flow to tank.

delivery can be passed through the orifice.

Figure 4

5