Section IV- INSTALLATION and OPERATING INSTRUCTIONS

NOTE

A. INSTALLATION DRAWINGS

These pumps must be driven in the direction of the

arrows cast on the pump ring. If it is desired to change

B. DRIVE CONNECTIONS

the direction of drive rotation, it is necessary to reverse

the ring. (See Section VI-B-D and Figure 9. )

CAUTION

CAUTION

Vickers pump shafts are designed to be installed in

Never drive a pump in the wrong direction of rotation.

Seizure may result, necessitating expensive repairs.

tap. Pounding can injure the bearings. Shaft

tolerances are shown on the pump installation

drawings. (See Table I.)

D. PIPING AND TUBING

1. All pipes and tubing must be thoroughly cleaned

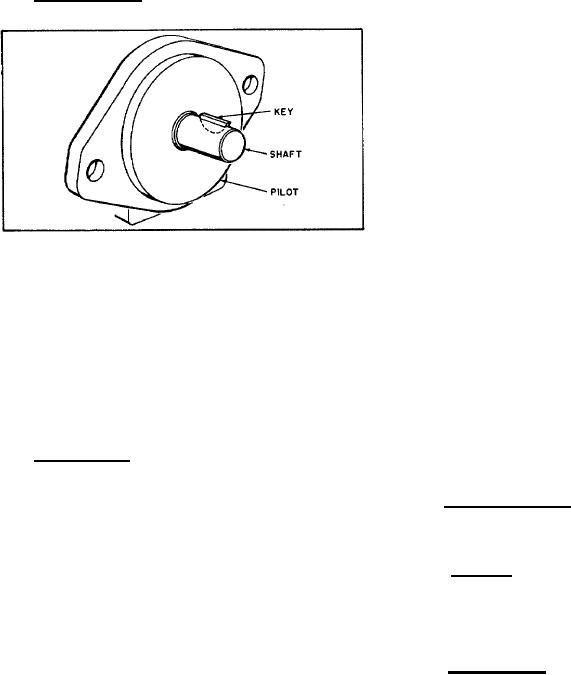

1. Direct Mounting - A pilot on the pump mounting

before installation. Recommended methods of cleaning

flange (Figure 5) assures correct mounting and shaft

are sand blasting, wire brushing and pickling.

NOTE

For instructions on pickling refer to Vickers instruction

sheet M-9600.

2. To minimize flow resistance and the possibility of

leakage, only as many fittings and connections as are

necessary for proper installation should be used.

3. The number of bends in tubing should be kept to a

minimum to prevent excessive turbulence and friction of

oil flow. Tubing must not be bent too sharply. The

Figure 5

recommended radius for bends is three times the inside

diameter of the tube.

and shaft alignment, provided the pilot is firmly seated in

the accessory pad of the power source. Care should be

E. HYDRAULIC FLUID RECOMMENDATIONS

exercised in tightening all flange mounting screws to

prevent misalignment.

The oil in a hydraulic system serves as the power

transmission medium. It is also the system's lubricant and

If gaskets are used between flanges, they should be

coolant. Selection of the proper oil is a requirement for

installed carefully so as to lay flat. Shaft keys and

satisfactory system performance and life. Oil must be

couplings must be properly seated to avoid slipping and

selected with care and with the assistance of a reputable

possible shearing.

supplier.

2. Indirect Drive - Chain, spur gear or vee belt

TWO IMPORTANT FACTORS IN SELECTING AN OIL

pulley drives may also be used with these pumps. Flat

ARE:

belt drives are not recommended because of the

1. Antiwear Additives - The oil selected must contain

possibility of slipping.

the necessary additives to insure high anti-wear

characteristics.

To prevent excessive side loads on the pump

bearings, it is important to check for correct alignment

2. Viscosity - The oil selected must have proper

and guard against excessive belt or chain tension.

viscosity to maintain adequate lubricating film at system

operating temperature.

C. SHAFT ROTATION

SUITABLE TYPES OF OIL ARE:

Vickers pumps are normally assembled for righthand

(clockwise) rotation as viewed from the shaft ends. A

1. Crankcase Oil meeting API service classification

pump made for lefthand rotation is identified by an "L" in

MS. The MS (most severe) classification is the key to

the model code (See Table II).

proper selection of crankcase oils for Mobile hydraulic

systems.

6