(2) Install the chain sprocket on the output shaft.

(3) Obtain a 10 ft. length of strong cord (50 lb. test) and a reliable hand-held spring scale such as the one

supplied with each paver Duo-matic system for ade line tensioning. (0 to 100 lbs. capacity).

(4) Tie one end of the cord to a sprocket and tooth, then wind several wraps around the sprocket hub and attach

the spring scale hook.

(5) Pull on the scale to tighten the cord and use your free hand to start rotation of the sprocket. (See Figure 14)

Observe the amount of pull required to keep the sprocket turning.(See Figure 15)If the pre-load is correct, a pull of 16

to 24 lbs. will be required. (This equals 40 to 60 inch pounds of torque; 16 to 24 x 2.5" radius of sprocket hub). If more

than 24 lbs. of pull is required, add some shim thickness to loosen the pre-load. If less than 16 lbs. is required, remove

some shim thickness.

CASE REPAIR

J.- It is vitally important that all bearing bores in the transfer case be in "new part" condition in order for bearings and

shafts to be accurately aligned and rigidly held. If a bore is worn over-size or out-of- round by an old bearing, a

replacement bearing will fail rapidly. This is due to the shock loading which results from a hammering action and from

misalignment of the shaft.

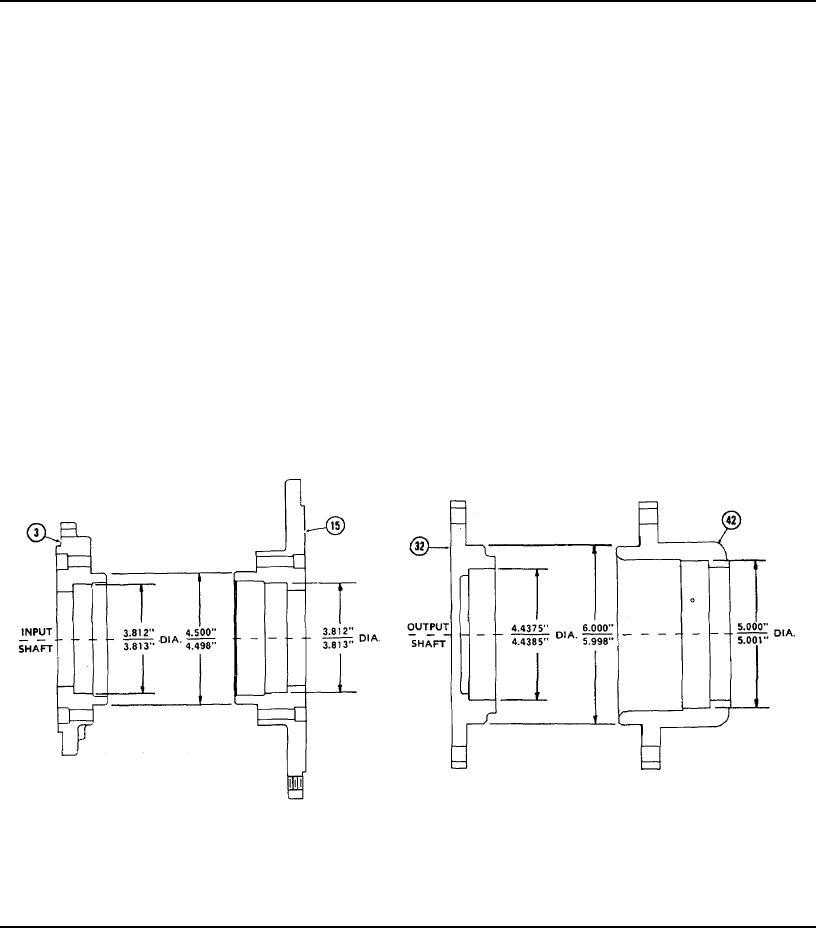

If parts have failed in a case, or severe mismatch of gear teeth has produced a poor "wear pattern" the case bores

should be checked by a machinist, using micrometers, dial indicators, etc. The factory dimensions given in Figures 16

thru 18 will provide the necessary checking details. If serious discrepancies are found, the case should be replaced, or

field re-built to new condition.

Bearing retainers and carriers as shown in Figure 16 must also have accurate bore and diameter. Re- place any

ones that do not conform to specified tolerances.

Removable Bearing Supports Figure 16

Page 107