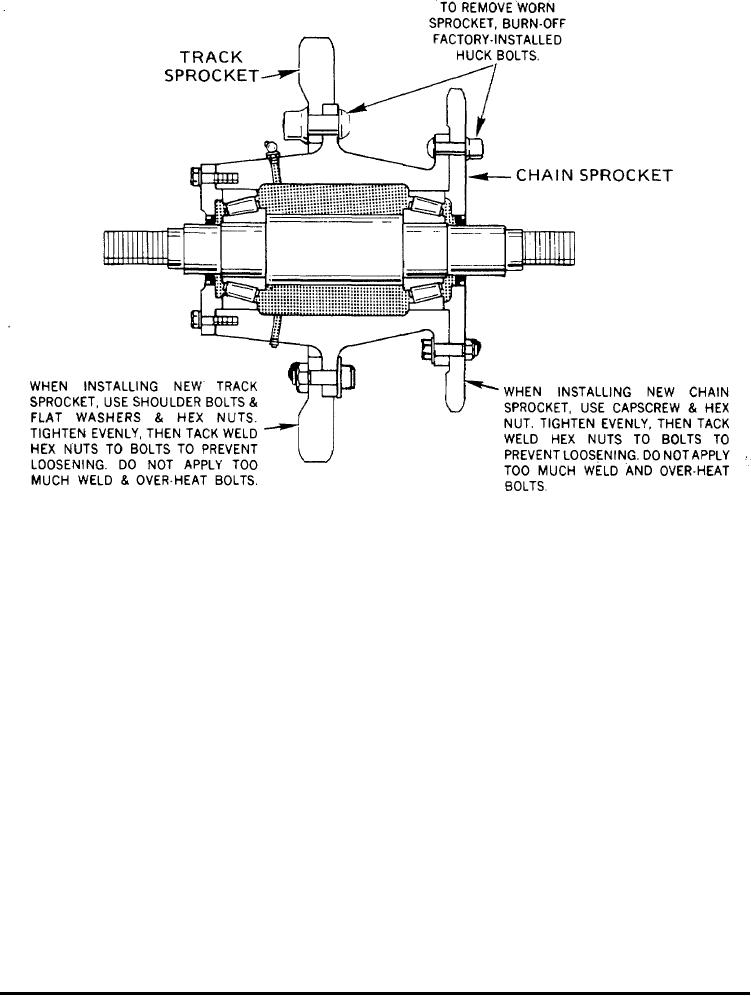

Cross-section Thru Track Drive Sprocket Assembly Showing

Factory and Field Methods of Sprocket Attachment

Figure 9

REPLACEMENT OF TRACK DRIVE & CHAIN SPROCKETS WHICH WERE HUCK-BOLTED TO HUB

The two-piece drive sprockets are attached to their hub assembly at the factory by means of "Huck Bolt"

fasteners. These special bolts, which employ a high pressure swaging principal for application of the "nut"

element, cannot be unfastened, but must be burned off when replacement of the sprocket halves is required.

(See Figure 9) The special fastener is used at this point to prevent any loosening of sprockets.

When sprockets become worn and must be replaced, use shoulder bolts of the correct length and hex nuts, in

place of the Huck Bolts. Important! Be sure that the bolt shoulder does not contact the hex nuts when

tightened. Use flat washers under the bolt head, if necessary, to prevent this occurrence. When all bolts are

tightened evenly, tack weld each nut to its bolt so that no loosening of the bolts is possible. (See Figure 9) Do

not apply too much weld so that the bolt is overheated and stretched.

CHAIN SPROCKETS

The chain sprockets are also attached to the hub at the factory by means of "Huck Bolts". These special

fasteners must be burned off and replaced by shoulder bolts when a new chain sprocket is required. Again it is

recommended that the hex nuts be tack welded to the bolts after tightening, so that there is no chance of

loosening during operation. Page 102

Page 102