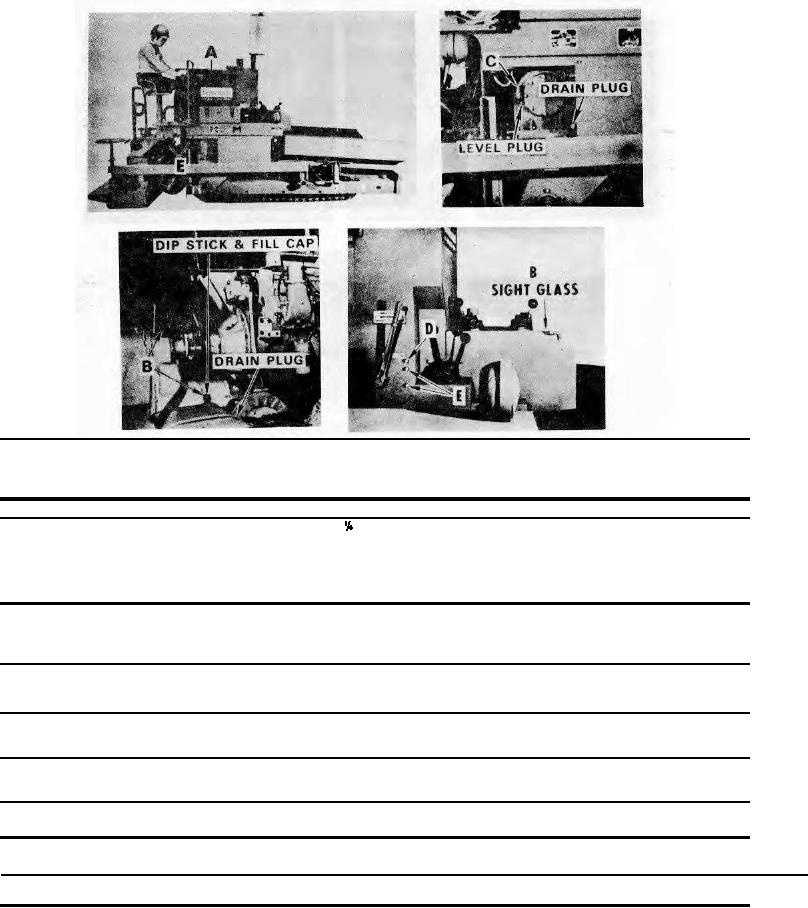

ASPHALT PAVER LUBRICATION CHART

ITEM REQUIRING

TEXACO

LUBRICANT

LOCATION

LUBRICATION

LUBRICATING INSTRUCTIONS

RECOMMENDED

A

Engine:

Refer to Lubrication Requirements in Engine Instruction Manual.

Keep filled to show " on dipstick. Sight glass must show oil

flow during operation. Seasonally, drain, back-flush filter screen

EP90 Universal Gear

Lubricant*

B

Main Transmission:

and case. Drain and re-fill with fresh lubricant (See Instruction

(Flush with Rando AA

Oil)

Manual - Section 11 for details}.

Keep filled to level hole. Seasonally, drain, flush and re-fill with

EP90 Universal Gear

Lubricant*

C

Power Transfer Cases:

fresh lubricant.

(Flush with Rando AA

Oil)

General Grease Lubricated

D

Bearings and Pivot Points:

One pump of gun each day.

Marfak # 0

(Requiring Daily Lubrication)

General Grease Lubricated

E

Bearings and Pivot Points:

One pump of gun each week.

Marfak # 0

(Requiring Weekly Lubrication)

Each day spray all track pins. Spray all slat conveyor chains

Track Pins, Slat Conveyor

Incomplete loops). Remove deck plates and spray both track drive

Fuel Oil

F

Chains, Track Drive Chains

chains. (Use oil spray accessories from screed heater system].

Track and Feed Clutch

Seasonally wash out and repack bearings and lube chamber. Re-

G

Bearings:

place grease seals (See Instruction Manual - Section 11).

Marfak # 0

Track Sprockets and

Seasonally remove plugs, install temporary fitting, add grease

H

Track Idlers:

until fresh grease extrudes from opposite hole. Remove plugs.

Marfak # 0

K

Conveyor Drive Chains:

Once each week coat all conveyor drive chains lightly.

EP 90 Universal Gear

Lubricant

*IMPORTANT NOTE:

Never mix brands of lubricant in paver gear cases. Chemical inter-action can occur to produce harmful, non-lubricating compounds. If uncertain

of lubricant

in a gear case, drain, flush and re-fill. DON'T JUST ADD MORE LUBRICANT!

(See Over)

Page 95