LUBRICATION - GENERAL SUGGESTIONS

PROPER LUBRICATION:

Proper Lubrication helps obtain top equipment performance and minimum down-time from worn out

bearings. Make it a daily practice. Be sure to comply with all lubrication instructions on the following Lubrication

Chart. Do not neglect any area or detail!

TOO MUCH GREASE:

Too Much Grease pumped into bearing housings can overheat bearings and reduce their service life. Use

good judgment.

TOO MUCH LUBRICANT PRESSURE

The use of too much pressure when lubricating a sealed bearing can blow-out the soft seal ring. Once the

seal is blown, the bearing has no grease retention ability and no protection against the entry of dirt into the race

area. Rapid failure results!

When using a hand operated grease gun, stop pumping as soon as the easy stroking begins to change to a

hard pumping requirement. When using a pressurized grease system, develop a "feel" for the correct pressure

of gun against fitting for automatic pressure relief in case the bearing be- comes filled.

SELECTION OF LUBRICANTS:

Texaco Lubricants are recommended on the lubrication chart following. Use only recommended lubricants.

GOOD HABITS:

Cleanness when lubricating is vital! The grit which is always present around grease fittings and oil reserves

can destroy a good bearing surface rapidly if it is forced inside with the lubricap.

When using a grease gun, wipe the nozzle clean before use.

Wipe grease fittings absolutely clean before each application or keep them covered with the special plastic

Lubricaps which are on each paver fitting when it leaves the factory. Keep lubricaps clean while they are off the

fittings. Leave an excess of grease on each fitting.

Don't wipe it off until the next greasing. It protects the fitting.

Use grease gun with cartridge type supply unit for positive elimination of dirt and abrasive particles in the new

grease.

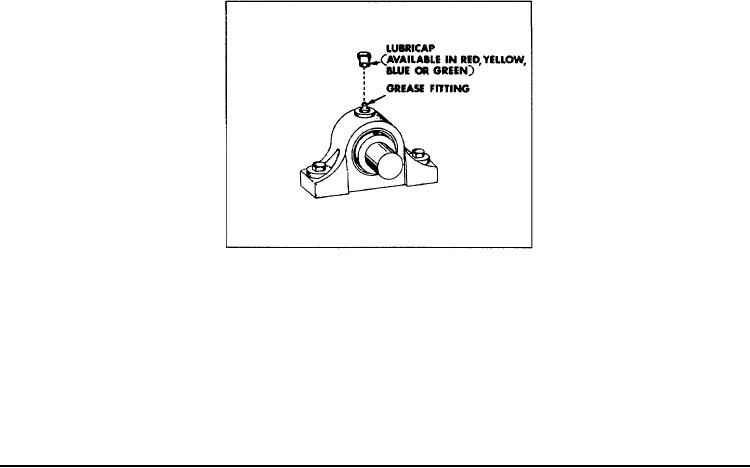

Plastic Lubricap for Bearing Grease Fittings

Figure 2

COLOR CODED LUBRICAPS

Lubricaps can be installed on all fittings to keep the area around the grease fittings free from dirt and dust.

This Neoprene cap is easily removed and replaced. These inexpensive Lubricaps are available in quantities

and can be ordered for placement on equipment in the field. Lubricaps are available in colors, so the customer

can establish a coding system for different types and time intervals of lubrication. Grease guns and lubricant

containers with matching color coding make correct lubricating routines easier.

Correct lubrication practices and continued use of the Lubricaps will insure the customer a longer bearing life,

as well as eliminate many hours of unnecessary down time. It is important that the lubrication requirements be

thoroughly under- stood and followed. SCHOOL YOUR LUBRICATION MAN.

Page 92