be maintained. When the Extension is moved farther

from the switch a lower level of material will be

maintained.

IMPORTANT! This adjustment should be made

during an actual paving run so that the

efficiency of the setting can be tested. Different

materials will require different settings of the

Extension, as there is a great variation in the

way materials move. WARNING! Do not set

extensions unless the Console Feed Switch is in

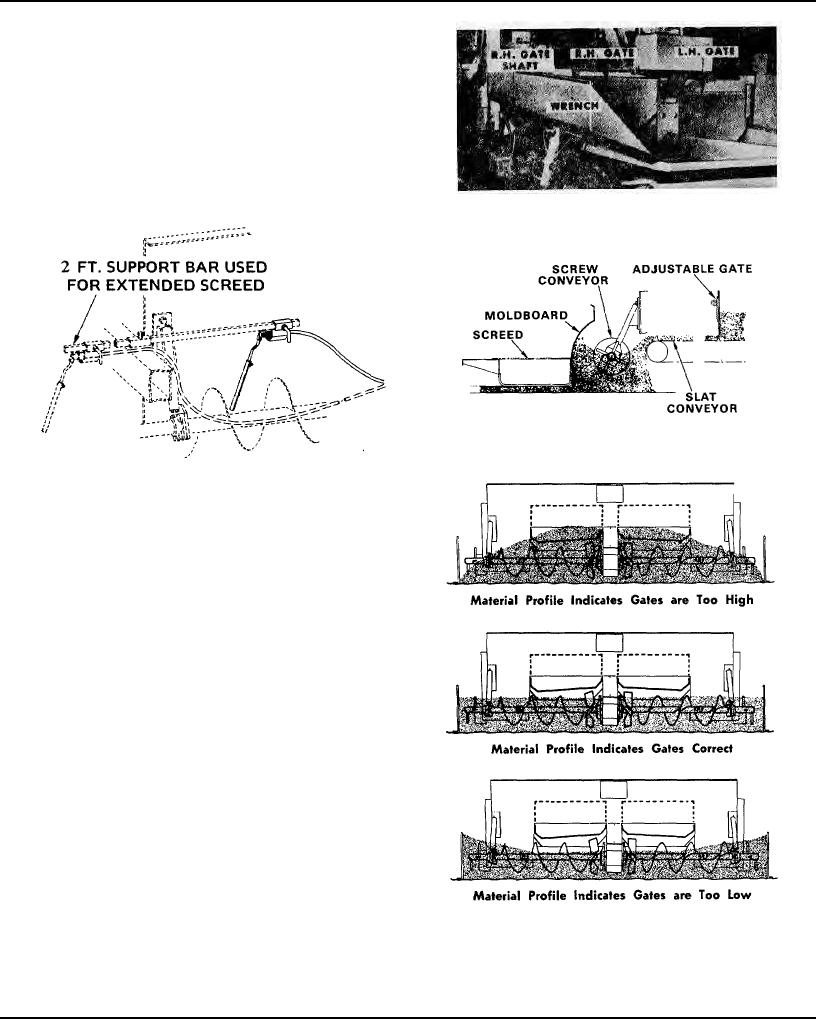

Adjusting RH Hopper Gate Height

the OFF position.

Figure 15

Schematic Side View Of Material Feed System

Figure 16

Range of Depth Feeler Switch Location

Figure 14

TO ADJUST HOPPER GATES

A hopper gate for each half of the material conveying

system regulates the depth of material moved from the

hopper to the spreader screw. The height of each gate is

adjusted separately by manual turning of the gate shaft

which operates a pinion gear to drive the rack attached to

the gate (See Figure 15).

Correct adjustment of the gates is important to good

paving. Best paving results are achieved when the

material level is approximately even with, or slightly

below the tops of the spreader screws. If material is deep

near the center of the screed and there is very little near

the ends, the gates are too high . If material is deep at

the ends of the screed and there is very little near the

center, the gates are too low. This tell-tale "material

profile" is the best way for an operator to judge the gate

settings. (See Figure 17). Usually a lower gate setting will

produce a smoother run than too high a gate setting.

Comparison Of Gate Height To Material Feed

Figure 17

Page 51