MANUAL OPERATION OF MATERIAL FEED

The two parallel but separate material feed systems

are controlled by toggle switches on the operators

console. These switches engage and disengage electric

clutches. (See Figures 3 and 4). The switches are three

position; MANUAL-OFF-AUTO. When the paver is in

Forward gear with engine running each feed system

combination of one slat conveyor and one screw conveyor

will operate whenever the toggle switch is set to

MANUAL. The operator must observe the feed and

operate the switch to keep material ahead of the screed

but not flowing over the mold board.

AUTOMATIC OPERATION OF MATERIAL FEED

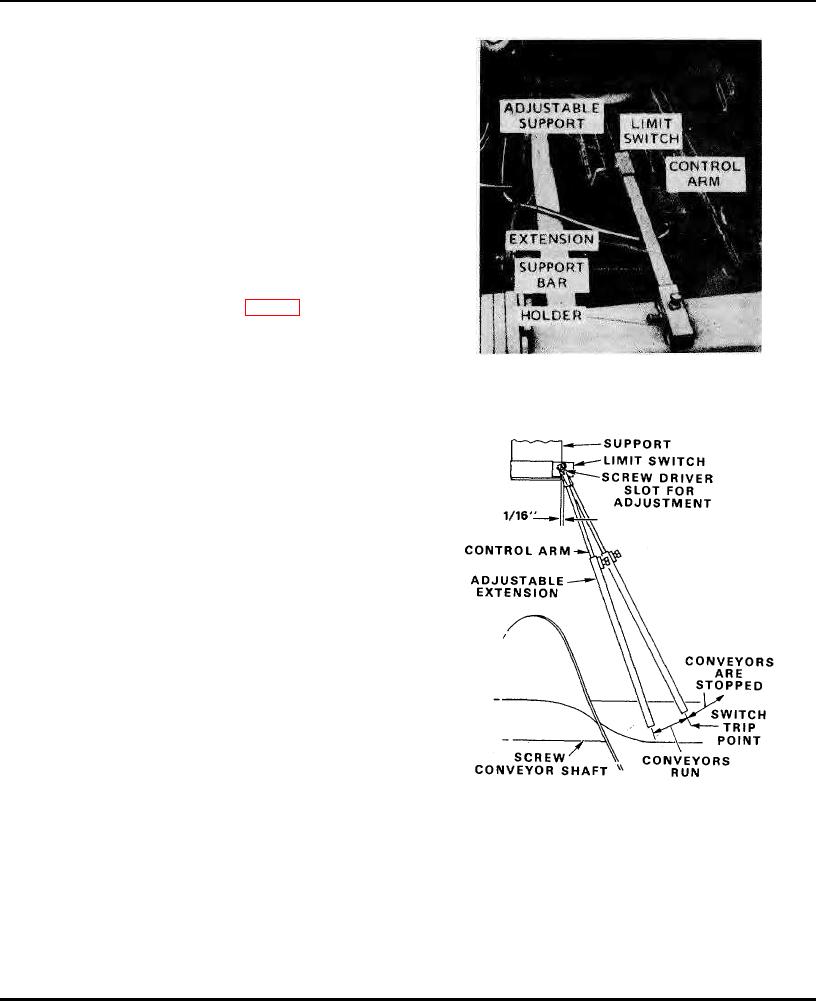

The depth feeler assembly can be quickly set for

automatic operation as follows: (See Fig. 12 & 13)

1. Loosen the control arm clamp so that it is loose on

the switch shaft.

2. Lower the arm to within A" of the positive stop which

Adjustable Material Depth Control Switch

keeps it from swinging farther downward. (A spacer can

with Feeler Arm - RH Assembly Shown

be used to hold the 1/16 setting).

Figure 12

3. Turn the switch shaft until an audible click indicates

that the internal contacts have closed, then while holding

that setting, tighten the clamp on the control arm.

4. Start engine and move feed switch on the console to

AUTO.

5. Manually raise and lower control arm to make sure

switch starts and stops conveyor at the point set.

6. To set the depth of material desired, move the

Extension which is clamped to the Control Arm. When

the extension is moved closer to the switch a higher

level of material at that point will

Recommended Setting Of Control Assemblies

Figure 13

Page 50