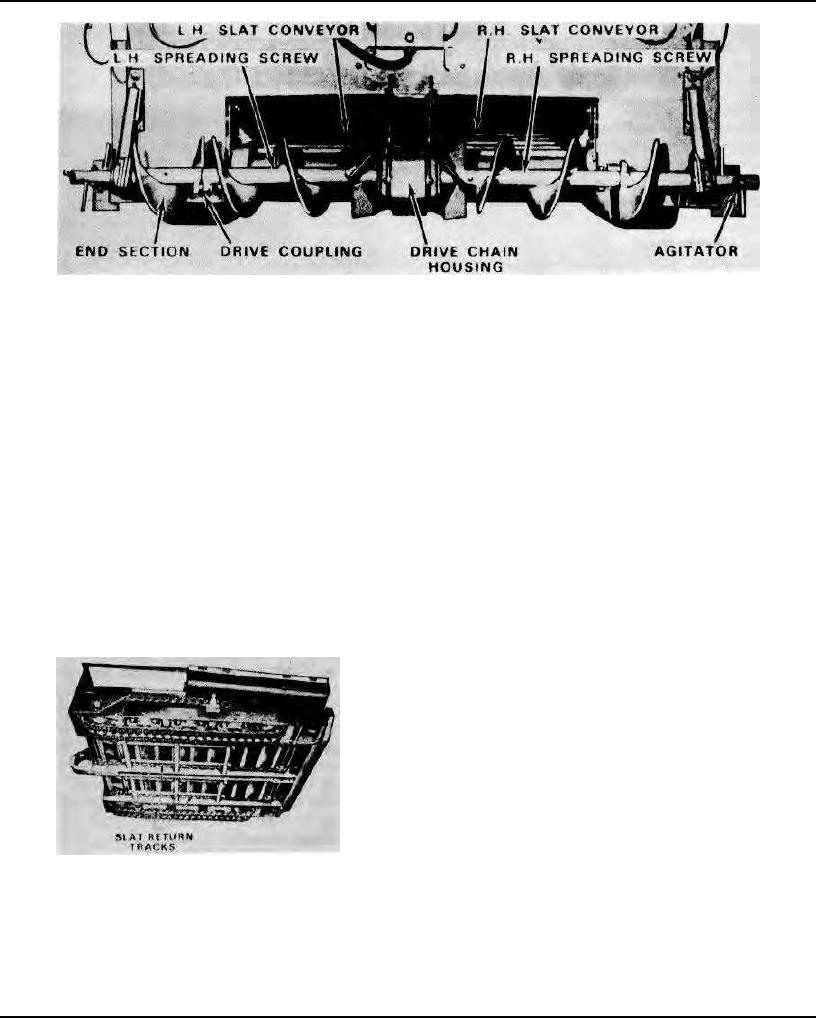

Slat Conveyors and Spreading Screws

(Screed Removed)

Figure 5

IMPORTANT! The slat conveyors are

SLAT CONVEYORS

Two slat conveyors move material from the bottom of

built to run in only one direction. When

the receiving hopper through parallel tunnel areas to each

the paver is shifted into Reverse gear for

backing, a micro switch at the gear box is

of the two spreading screws which operate in conjunction

actuated to open the conveyor clutch

with the slat conveyors. The depth of material moved is

circuits so that no reverse movement of

varied by manual adjustment of fixed gates located at the

the slats can occur. This limit switch

head end of each tunnel. (See Figure 5)

Slat speed is fixed, unless an optional two-speed

(Section 8, Figure 4) must always be

transmission unit is purchased to permit a 30% speed

kept in adjustment!

shift when required. With the fixed speed arrangement

the drive may be either the high or the low range.

SPREADING SCREWS

Each slat conveyor and its companion spreading screw

The two spreading screws which operate in conjunction

are controlled by electric clutch action. The clutches can

with the slat conveyors receive material as it is brought

be engaged manually by toggle switch movement at the

through the tunnel areas near the center of the tractor

operators console, or can be controlled automatically by a

unit. The opposing pitch of the screw blades forces the

material depth feeler if the console toggle switch is set at

material outward toward the ends of the screed. A set of

AUTO. (See details of automatic operation in following

special blades on each spreader screw at its inner end

paragraphs covering conveyors).

has a reverse slant which assures placement of adequate

material in the center area. Agitators at the outer end of

each screw perform a stirring function to prevent material

compaction by the screws against the retaining blades.

Spreader screws are offered in two diameters for

different feeding rates; 12" diameter for lower volume

feeding and 14" diameter for higher volume feeding.

Whenever extreme wear reduces the diameter of a screw

by the tips should be built up or the blades refaced to

the original O.D. (See Maintenance Section 11).

When less than 10 ft. wide paving is done, the end

flight of the screw on the cut-off side is uncoupled by

sliding a key outward. When uncoupled the outer flight no

longer moves material. (See Figure 5).

Bottom View of Tractor Assembly

Figure 6

Page 48