SECTION VI

Asphalt Spreading System (Feed)

MATERIAL FEED SYSTEM

The feed system is arranged to give the operator

good control of material movement and distribution.

From his seat almost directly over the spread-screws,

the operator has an unobstructed view of material

distribution ahead of the screed.

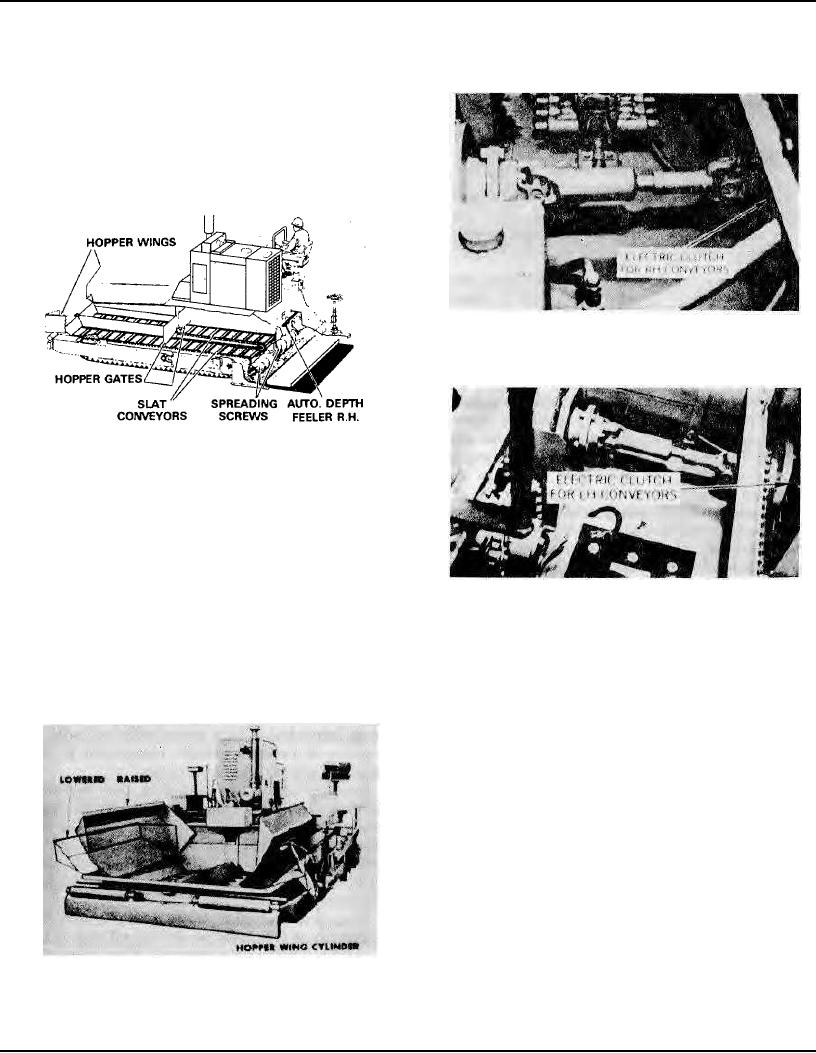

Electric Clutches - R.H. Walkway Removed

Figure 3

Material Flow Diagram

Figure 1

HOPPER WINGS

The two hinged hopper wings which can be raised and

lowered hydraulically to permit complete emptying of

the large hopper should be operated after each supply

truck has pulled away and cleared the hopper area.

They should never be raised when a truck is at the

Electric Clutches - L.H. Walkway Removed

paver. (See Figure 2)

Figure 4

The hydraulic cylinders which raise each of the

hopper wings are powered from the same hydraulic

pressure line and one will normally preceed the other

ASPHALT FEED CLUTCHES (Slat and Screw

in reaching the fully raised and fully lowered attitude.

Conveyors)

The two slat conveyors and the two screw conveyors

which combine functions to move asphalt from the

hopper to the area ahead of the trailing screed, are

operated by means of two electromagnetic clutches.

Each clutch starts or stops the movement of one side of

the feed system (Right hand or Left hand). By chain and

sprocket connection, one slat conveyor and one screw

conveyor operate simultaneously to feed one side.

(See Figures 3 and 4) Each clutch is operated by

means of a toggle switch on the operator's console, or

by an auxiliary switch on the paver deck beneath the

operator's seat.

(The auxiliary switch is for the

convenience of the screed man when he chooses to

control the feed manually for some special

requirement).

Complete information on the care and adjustment of

Tilting Hopper Wings

electric clutches is contained in the Mechanical

Figure 2

Maintenance Section 11)

Page 47