TM 5-3895-385-23-1

0151

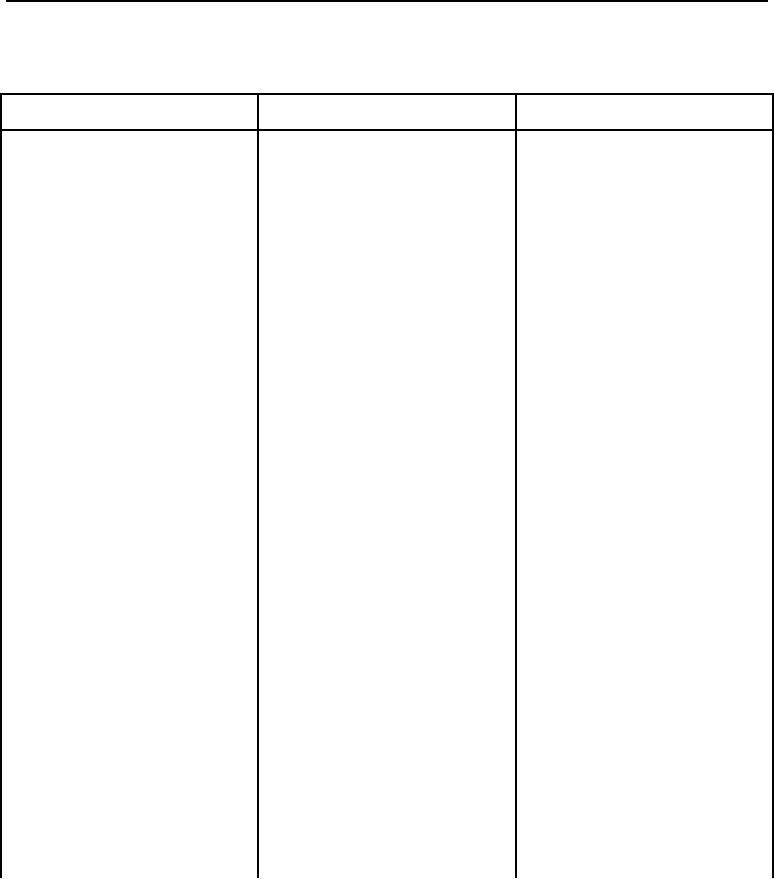

Table 1. Right Track Reverse EDC Fault Troubleshooting Procedures -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. Attempt to turn right track on at

maximum speed in the reverse

direction using joysticks (TM 5-

3895-385-10).

4. Measure voltage (WP 0443, Vol

1. If voltage reads a minimum of

3) between main wiring harness

1.5 Volts Direct Current (VDC),

W1 J18 Pin D and main wiring

replace the propulsion pump

harness W1 J18 Pin C (WP

(WP 0320, Vol 2).

0451, Vol 3, Figure 10) while

connector is plugged into

propulsion pump.

2. If Voltage reads below 1.5 VDC,

turn keyless engine switch to the

OFF position (TM 5-3895-385-

10), and proceed to next

malfunction.

3. Propel controller (Electronic

1. Disconnect main wiring harness

Control Module (ECM)) has

W1 J2 from propel controller

damage or loose pin.

module ECM (WP 0451, Vol 3,

Figure 2).

2. Check propel controller module

1. If propel controller module ECM

ECM for damage or loose pin.

has damage or loose pin,

replace propel controller module

ECM (WP 0399, Vol 2).

2. If no damage is found, proceed

to next malfunction.

4. Main wiring harness has an

1. Measure for continuity (WP

1. If continuity is present, proceed

open circuit.

0443, Vol 3) between main

to next test.

wiring harness W1 J2 Pin 37 and

main wiring harness W1 J18 Pin

A (WP 0451, Vol 3, Figure 2 and

10).

2. If no continuity is present,

replace main wiring harness

(WP 0373, Vol 2).

0151-2