TM 5-3895-373-34

2.67

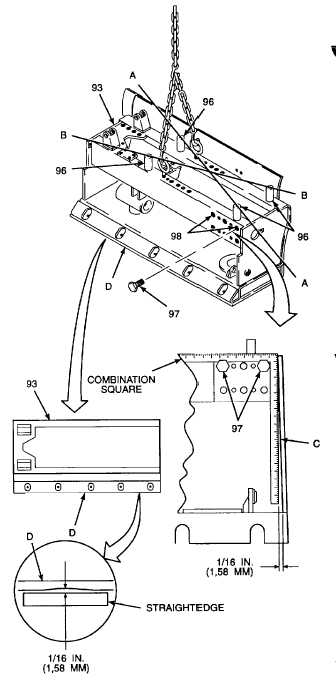

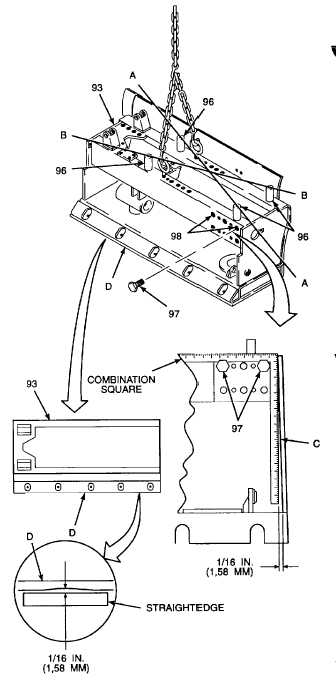

REPLACE MAIN SCREED FRAME - Continued.

C.

INSPECT.

1.

INSPECT MAIN SCREED FRAME.

WARNING

Main

screed

frame

weighs

approximately 700 lbs (318 kg). Main

screed frame will be suspended by a

chain hoist during inspection. Do not

allow personnel to move or work

beneath main screed frame while

suspended. Severe injury or death

can result from main screed frame

falling or dropping while suspended.

a.

With hex head screw caps installed in main

screed frame (93), suspend main screed frame

at a height of 1.0 to 2.0 in. (25,4 to 50,8 mm)

over work surface. Main screed frame must be

supported only by hex head screw caps.

b.

Measure distance between threaded bore (96)

centers, between points A-A and B-B, using a

straightedge.

c.

If distances between threaded bore center points

A-A and B-B vary greater than 1/16 in. (1,58

mm) between the two points, replace main

screed frame (93).

d.

Install hex head cap screws (97), used to hold

extension screed guide shaft support to main

screed, into threaded bores (98).

e.

Place a combination square against top shank

surface of hex head cap screws (97) and hold

against surface C of main screed frame (93),

holding top part of square flat against shank of

hex head cap screws.

f.

If surface C of main screed frame (93) is greater

than 1/16 in. (1,58 mm) from edge of

carpenter’s square at any point, replace main

screed frame.

g.

Place a straightedge across surface D. If any

point on surface D is greater than 1/16 in. (1,58

mm) from straightedge, replace main screed

frame (93).

h.

Visually inspect main screed frame (93) weld

joints and lower burner box for cracks or breaks.

Replace main screed frame if cracks or breaks

are detected at any point on frame.

GO TO NEXT PAGE

2-942