TM 5-3895-373-34

2.66.

REPLACE EXTENSION SCREED FRAME - Continued

D.

INSTALL - Continued.

1.

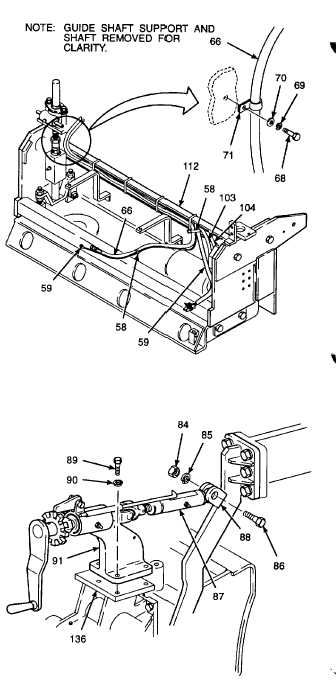

Route screed harness (59) and screed burner fuel

hose (66) through conduit channel of extension

screed frame (112).

m.

Install lockwasher (69) and flat washer (70) to

hex head cap screw (68).

Thread locking compound can cause

eye

damage.

Wear

safety

goggles/glasses when using. Avoid

contact with eyes. If compound

contacts eyes, flush eyes with water

and get immediate medical attention.

n.

Apply thread locking compound (Item 14,

Appendix B) to hex head cap screw (68) and

secure clamp (71) and burner fuel hose (66) to

extension screed frame inner plate.

o.

Install tie wraps (58) on screed harness (59),

screed burner fuel hose (66), and hydraulic

hoses (103 and 104). Refer to opposite

extension screed for proper tie wrap locations.

8.

INSTALL THICKNESS CONTROL COMPONENTS.

a.

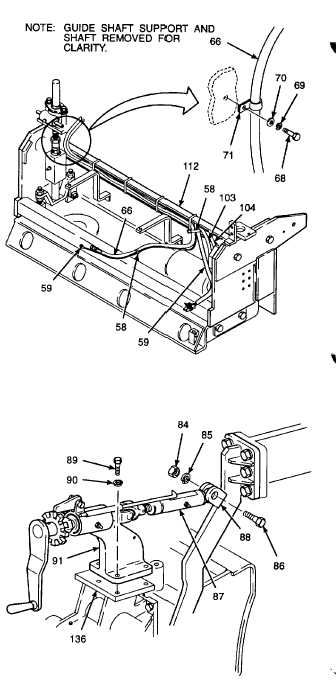

Set screed thickness control mounting bracket

(91) on guide shaft support (136). Align

mounting bracket mounting holes.

b.

Install lockwashers (90) onto hex head cap

screws (89).

c.

Apply thread locking compound (Item 13,

Appendix B) to threads of hex head cap

screws (89).

d.

Install

hex

head

cap

screws

(89)

and

lockwashers (90). Tighten hex head cap

screws to 90 lb-ft (122 N•m).

e.

Insert link (87) in screed arm bracket (88) and

install hex head cap screw (86) and lockwasher

(85). Apply thread locking compound (Item 13,

Appendix B) to threads of cap screw.

f.

Install hex nut (84). Tighten hex nut to 180 lb-ft

(244 N•m)

GO TO NEXT PAGE

2-918