TM 5-3895-373-34

D.

REPLACE - Continued.

6.

ALIGN CONVEYOR CHAIN ASSEMBLY.

a.

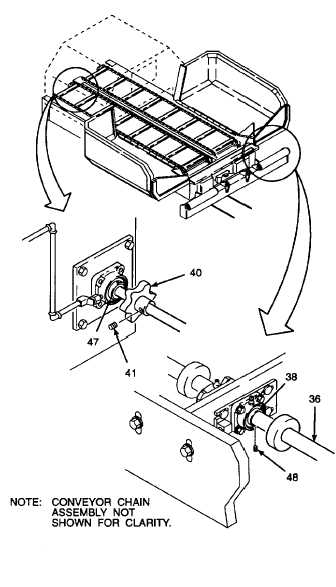

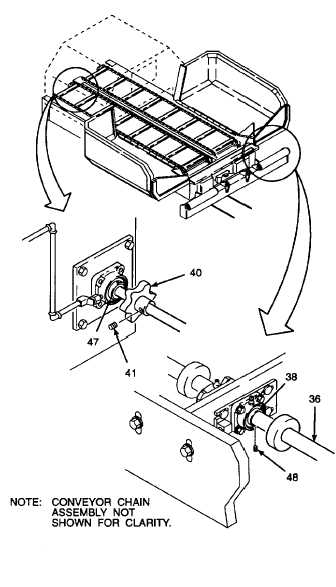

Visually check conveyor chain assembly in

tunnel opening. Chain assembly should be

centered in tunnel opening with sprocket

wheels (40) equal distance from bearing

units (47). If not, remove set screws (41)

on

both

sprocket

wheels

and

move

sprocket wheels to center conveyor chain

assembly in tunnel opening. Keep the

distance between sprocket wheels the

same as the chain assembly width.

Thread locking compound can cause eye

damage. Wear safety goggles/glasses when

using.

Avoid

contact

with

eyes.

If

compound contacts eyes, flush eyes with

water and get immediate medical attention.

b.

Apply thread locking compound to threads

of set screws (41).

c.

Install set screw (41). Tighten set screws

using socket wrench adapter and hex head

driver socket (Item 86, Appendix D) to 90

Ib-ft (122 N•m).

NOTE

After

the

conveyor

chain

assembly

is

installed on conveyor roller wheels and

sprocket wheels, it will be necessary to run

the conveyor to center the idler end of the

chain assembly and conveyor roller shaft.

d.

Loosen set screws (48) on bearing units

(38) at both ends of conveyor roller shaft

(36).

Use extreme caution when conveyor and

auger are operating. Stay clear of all moving

parts. Failure to do so may result in tools,

clothing, hands, or feet getting caught and

causing serious injury or death to personnel.

e.

Start engine and run conveyor in forward

direction

using

manual

operation

procedures

per

TM

5-3895-373-10.

Visually check alignment of conveyor chain

assembly and roller shaft (36). Chain

assembly should be running either in

center, or slightly off center without hitting

sides of machine frame. Stop conveyor.

Shut off engine and remove key from

ignition switch per TM 5-3895-373-10.

GO TO NEXT PAGE

2-847