TM 5-3895-373-34

2.61

REPLACE CONVEYOR CHAIN ASSEMBLY - Continued.

C.

INSPECT - Continued.

4.

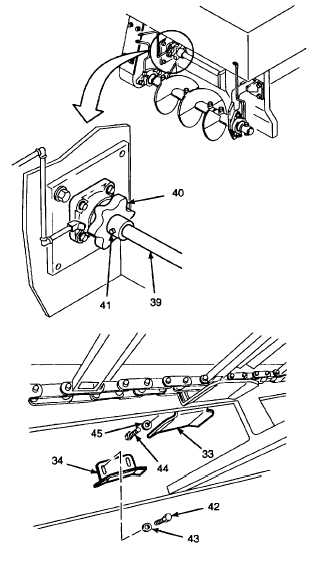

INSPECT

CONVEYOR

DRIVE

SHAFT,

BEARING UNITS, AND SPROCKET WHEELS.

a.

Visually inspect conveyor drive shaft (39)

for bends and cracks. Replace damaged

drive shaft per paragraph 2.64.

b.

Inspect sprocket wheels (40) for worn,

broken, or sharpened teeth. Replace

sprocket wheels per paragraph 2.64 if worn

or damaged.

c.

Move sprocket wheels (40) by hand to the

left and right to check for looseness. If

sprocket wheels are loose, tighten set

screws (41) to 90 lb-ft (122 N•m) using

socket wrench adapter and hex head driver

socket (Item 86, Appendix D).

d.

Check bearing units by spinning conveyor

drive shaft. Drive shaft should spin free

and easy with no grinding sound from

bearing

units,

or

rough

or

binding

movement in bearing units. Replace

damaged bearing units per paragraph 2.64.

D.

REPLACE.

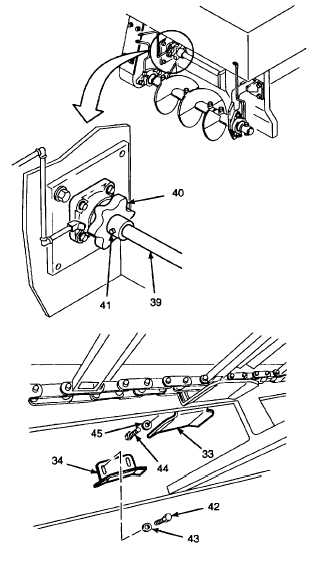

1.

REMOVE WORN OR DAMAGED OUTER AND

INNER CHAIN GUIDE BARS.

Wear safety goggles/glasses when

working underneath paving machine.

Falling

material

may

cause

eye

damage. If material contacts eyes,

flush

eyes

with

water

and

get

immediate medical attention.

a.

Remove hex head cap screws (42) and flat

washers (43) from outer chain guide bar

(34).

b.

Remove outer chain guide bar (34).

c.

Remove hex head cap screws (44) and flat

washers (45) from inner chain guide bar

(33).

d.

Remove inner chain guide bar (33).

Thread locking compound solvent

can cause eye damage. Wear safety

goggles/glasses when using. Avoid

contact with eyes. If solvent contacts

eyes, flush eyes with water and get

immediate medical attention.

e.

Clean threads of hex head cap screws (42

and 44) with thread locking compound

solvent and a cleaning cloth. Dry cap

screws with a clean, cleaning cloth.

GO TO NEXT PAGE

2-842