TM 5-3895-373-34

2.60

REPAIR HOPPER LIFT CYLINDER - Continued.

D.

REPAIR - Continued.

2.

INSTALL SPHERICAL BEARING.

CAUTION

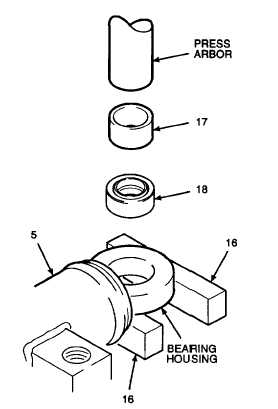

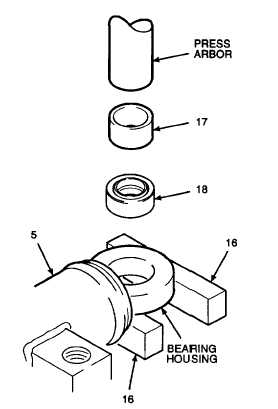

Place cylinder tube parallel blocks

(16) close to bearing bore when

pressing

spherical

bearing

(18).

Failure

to

place

parallel

blocks

correctly may lead to warping of the

cylinder tube (5).

a.

Set up cylinder tube (5) on hydraulic press. Use

parallel blocks (16) to support bearing housing.

CAUTION

Spherical

bearing

(18)

must

be

pressed straight into bearing bore. If

spherical bearing is allowed to tilt,

damage may result to both the

spherical bearing and bearing bore.

b.

Start spherical bearing (18) in bearing bore of

cylinder tube (5).

NOTE

Spherical

bearing

installation

will

require 500 to 700 lbs (2224 to 3114

N.m) force when pressed into bearing

bore.

c.

Place a 1.25 in. (32 mm) diameter spacer (17)

from universal puller kit onto outer race of

spherical bearing (18). Bring hydraulic press

down to meet spacer. Square spacer with face

of press arbor. Press spherical bearing squarely

into base bearing bore.

GO TO NEXT PAGE

2-830