TM 5-3895-373-34

C.

INSPECT - Continued.

WARNING

Compressed air used for cleaning

purposes will not exceed 30 psi (207

kPa). Use only with effective chip

guarding

and

personal

protective

equipment (goggles/face shield and

gloves). Failure to take proper

precautions may result in severe

injury or loss of vision.

b.

Use 30 psi (207 kPa) maximum compressed air

to blow any foreign material from preformed

packing grooves, seal grooves, inside of tube,

and threaded surfaces.

c.

Dry parts with a clean, lint-free cloth. Set dry

parts on clean surface. Place a clean, lint-free

cloth into open end of cylinder tube to prevent

contamination.

D.

REPAIR.

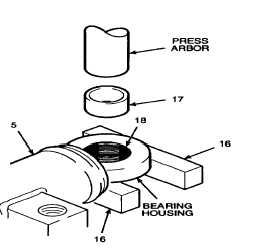

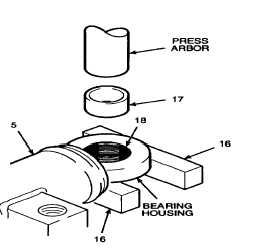

1.

PRESS OUT SPHERICAL BEARING.

CAUTION

Place cylinder tube support blocks

close to bearing bore when pressing

out spherical bearing. Failure to

place support blocks correctly may

lead to warping of the cylinder tube.

a.

Set up cylinder tube (5) on hydraulic press.

Place parallel blocks (16) under bearing housing

for support.

b.

Place spacer (17) from universal puller kit on

outer race of spherical bearing (18). Press

spherical bearing squarely out of bearing bore.

GO TO NEXT PAGE

2-829