TM 5-3895-373-34

2.58

REPLACE/REPAIR EXTENSION SCREED HEIGHT ADJUSTMENT- Continued.

D.

ADJUST.

NOTE

Lift jack assemblies may

be

adjusted independently of each other

by separating inner and outer height

adjustment knobs.

1.

ROTATE HEIGHT ADJUSTMENT KNOBS AND

RAISE EXTENSION SCREED BASE INTO

EXTENSION SCREED FRAME.

2.

RETRACT EXTENSION SCREED PER TM 5-

3895373-10.

3.

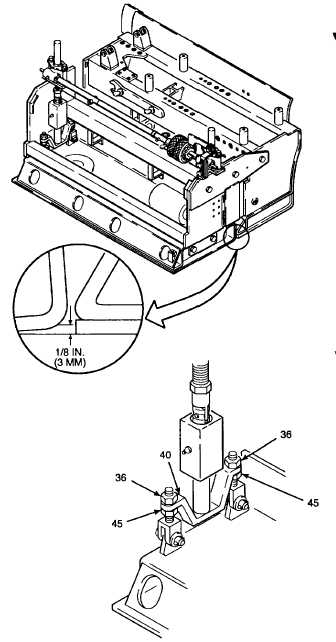

USE STRAIGHTEDGE TO VERIFY THAT

TRAILING EDGE OF EXTENSION SCREED

PLATE IS ON SAME PLANE AS MAIN

SCREED PLATE.

4.

USE STRAIGHTEDGE TO VERIFY THAT

LEADING EDGE OF EXTENSION SCREED

PLATE IS 1/8 IN. (3 MM) ABOVE BOTTOM

SURFACE OF TRAILING EDGE OF MAIN

SCREED PLATE.

5.

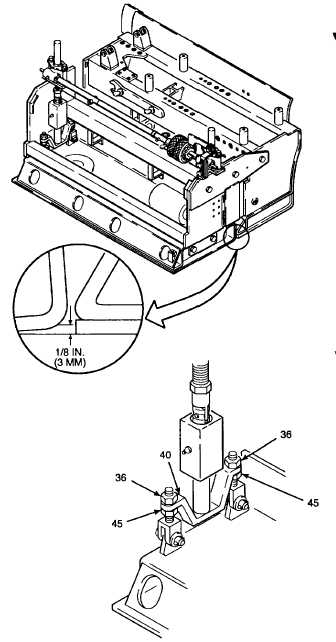

LOOSEN HEX NUTS (45). ADJUST HEX

NUTS (36) SO THAT THE LEADING EDGE OF

THE EXTENSION SCREED PLATE IS 11/8 IN.

(3 MM) ABOVE THE BOTTOM SURFACE OF

THE MAIN SCREED PLATE.

6.

TIGHTEN HEX NUTS (45) SO THAT THEY

ARE FLUSH AGAINST THE BOTTOM OF LIFT

BRACKET (40).

7.

TIGHTEN HEX NUTS (36) TO 320 Ib-ft (434

N.m) USING SOCKET WRENCH ADAPTER

(ITEM 6, APPENDIX D).

NOTE

FOLLOW-ON-TASKS: Burner chamber installed per TM 5-3895-373-20.

Blower motor installed per TM 5-3895-373-20.

Replace extension screed cover plates per TM 5-3895-373-20.

Install endgates per TM 5-3895-373-20.

END OF TASK

2-812