TM 5-3895-373-34

2.58

REPLACE/REPAIR EXTENSION SCREED HEIGHT ADJUSTMENT - Continued

C.

INSTALL.

1.

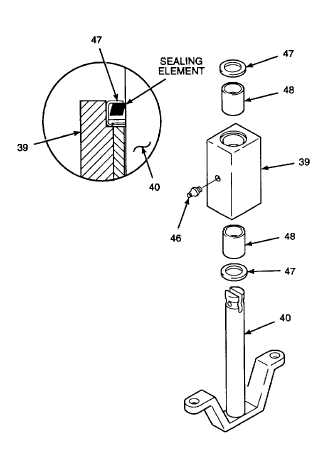

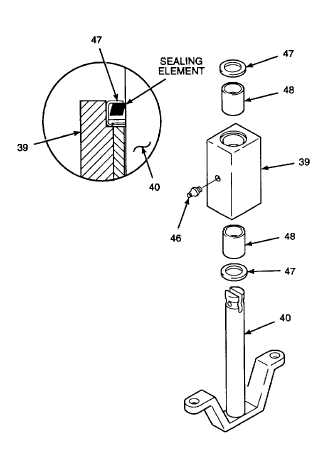

ASSEMBLE VERTICAL ADJUSTMENT BLOCK

ASSEMBLY.

a.

Use a hydraulic press frame and spacer from

universal puller kit and press one sleeve bushing

(48) into each end of guide block (39). Fully seat

bushings against seating edge in guide block.

b.

Lubricate sealing element of plain encased seals

(47) with light coating of grease.

Lubrication problems can cause poor

performance and equipment damage.

Ensure new seals are properly installed.

Improper installation of plain encased

seals can lead to inadequate lubrication

and lubricant contamination.

c.

Place plain encased seal (47) in position on

guide block (39). Make sure sealing element is

facing outer edge of guide block as shown.

d.

Press or evenly tap outer area of plain encased

seal (47) with plastic hammer and seat seal in

guide block (39).

e.

Lubricate lift brackets (40) with light coating of

grease.

f.

Slide lift brackets (40) through guide blocks (39).

g.

Thread lubrication fittings (46) into guide blocks

(39).

GO TO NEXT PAGE

2-806