TM 5-3895-373-34

2.17

DIESEL ENGINE REPAIR - Continued.

E.

INSTALL - Continued.

h.

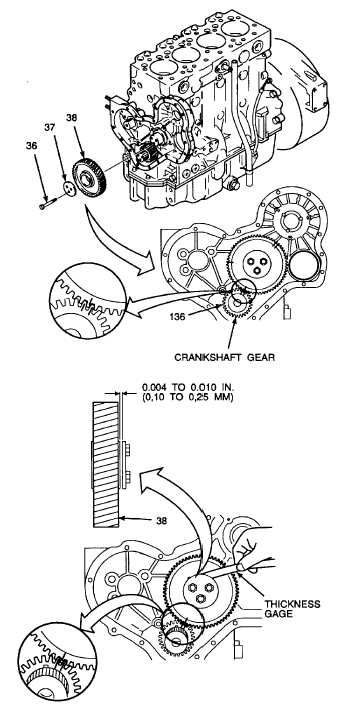

Turn crankshaft assembly (136) until two timing

marks on crankshaft gear are at the one o’clock

position.

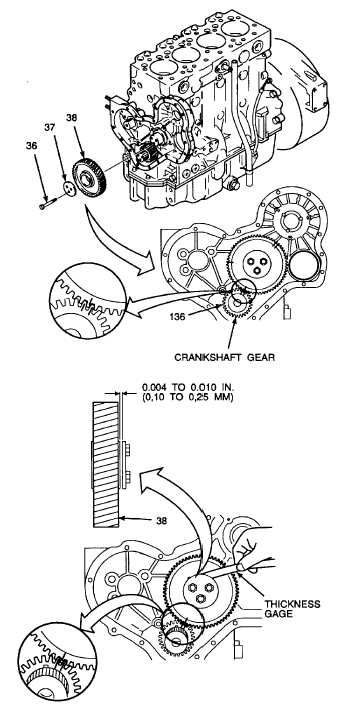

Ensure oil hole in idler gear hub

aligns with hole in engine block

before

installation

of

idler

gear.

Serious engine damage may result if

oil holes do not align.

i.

Install idler gear (38) with single timing mark

aligned between two timing marks on crankshaft

gear.

j.

Install retaining plate (37) and hex head cap

screws (36). Tighten hex head cap screws to 30

ft-lb (40 N.m).

k.

Use a thickness gage to measure idler gear (38)

end float. Idler gear end float must be 0.004 to

0.010 in. (0, 10 to 0, 25 mm).

NOTE

With correct timing mark on idler gear

aligned with two timing marks on

crankshaft gear, there will also be a

single mark at 9 o’clock and a dual

mark at 2 o’clock.

GO TO NEXT PAGE

2-230