TM 5-3895-373-34

2.16

ENGINE REPLACEMENT - Continued.

C.

INSTALL..-.Continued.

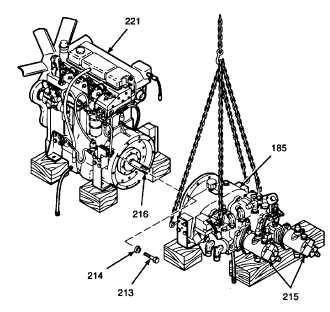

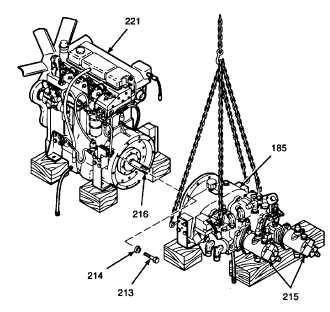

Pump and gearbox weigh approximately

410 lbs (187 kg). Ensure chain assembly

and sling strap are in good condition and

are of correct capacity. Ensure sling

strap is positioned between pump drive

gearbox and flywheel housing. Chain

assembly must be attached securely to

front lifting bracket. Failure to do so may

result in the engine and pump assembly

shifting causing equipment to fall. This

may cause serious injury or death to

personnel.

Do not allow pump drive gearbox (185) to

swing and hit engine when aligning drive

shaft with mating gear in gearbox. Move

gearbox slowly in place using overhead

hoist. Gearbox mounting surfaces may be

damaged if gearbox was allowed to strike

engine.

NOTE

Cribbing underneath pump drive gearbox

(185) and hydraulic pumps has to be

shifted to support pump drive gearbox and

hydraulic pumps during installation to

engine.

h.

With the help of two persons, align drive shaft

(216) with mating gear in pump drive gearbox

(185) slowly using overhead hoist. Install

gearbox onto engine (221). Do not let gearbox

hit engine. Shift cribbing over underneath

gearbox and hydraulic pumps (215) as shown.

i.

Install lockwashers (214) onto hex head cap

screws (213).

Thread locking compound can cause eye

damage. Wear safety goggles/glasses

when using. Avoid contact with eyes. If

compound contacts eyes, flush eyes with

water

and

get

immediate

medical

attention.

NOTE

When

installing

the

pump

drive

gearbox onto the engine, the top two

mounting holes on gearbox are left

open. Hardware is installed when

battery and slave cable clamps are

reinstalled in a later procedure.

j.

Apply thread locking compound to threads of ten

hex head cap screws (213) and install cap

screws into cover plate of pump drive gearbox

(185) securing it to engine (221). Do not install

cap screws and lockwashers into top two

mounting holes. Tighten cap screws 42 Ib-ft (57

N•m).

GO TO NEXT PAGE

2-120