TM 5-3895-373-34

2.16

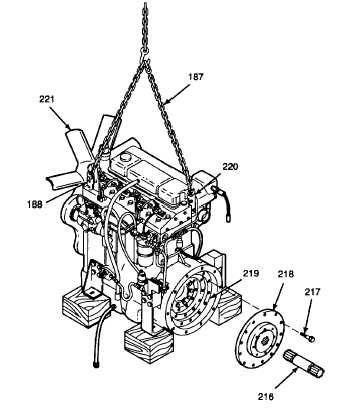

ENGINE REPLACEMENT - Continued.

C.

INSTALL Continued.

Do not set engine down so that the

weight of the engine rests on the

engine oil sump. Place cribbing

underneath

engine

mounting

brackets. Failure to do so may result

in damage to the oil sump.

c.

With the help of another person, lift and guide

engine (221) up out of engine stand and lower

down onto cribbing as shown.

d.

Remove chain assembly (187) from lifting

brackets (188 and 220).

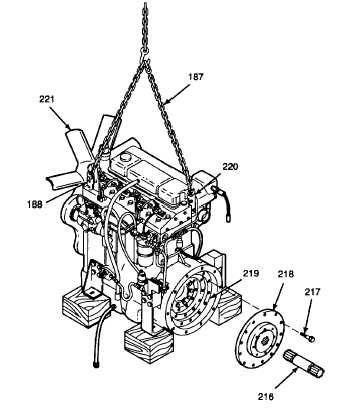

3.

INSTALL

PUMP

DRIVE

GEARBOX

AND

HYDRAULIC PUMPS, DRIVE PLATE, AND DRIVE

SHAFT ONTO ENGINE.

a.

Align mounting holes on drive plate (218) with

mounting holes on engine flywheel assembly

(219).

Thread locking compound can cause

eye

damage.

Wear

safety

goggles/glasses when using. Avoid

contact with eyes. If compound

contacts eyes, flush eyes with water

and get immediate medical attention.

b.

Apply thread locking compound to threads of

socket head cap screws (217) and install cap

screws and drive plate (218) onto engine

flywheel assembly (219). Tighten hex head cap

screws 37 lb-ft (50 N•m).

Anti-seize compound can cause eye

damage. Wear safety goggles/glasses

when using. Avoid contact with eyes. If

compound contacts eyes, flush eyes

with water and get immediate medical

attention.

c. Apply a light coating of anti-seize compound to

the gear splines on drive shaft (216).

d. Install drive shaft (216) into drive plate (218).

GO TO NEXT PAGE

2-118