TM 5-3895-373-34

2.71

REPLACE MAIN AND EXTENSION SCREED PLATES - Continued. --

B.

REMOVE - Continued.

2.

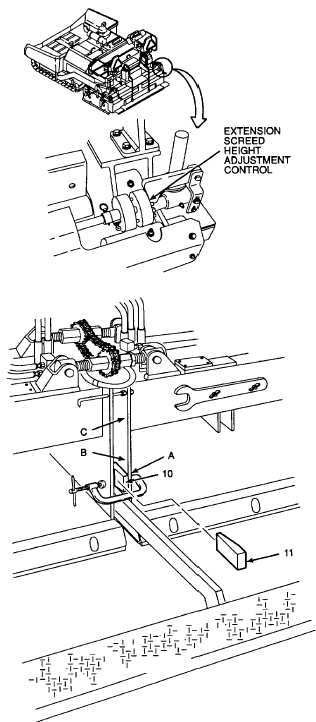

ALIGN EXTENSION SCREED PLATES FLUSH

WITH MAIN SCREED PLATE.

a.

Lay a straightedge across extension screed

plate and main screed plate trailing edges.

b.

Have second person use extension screed

height adjustment per TM 5-3895-373-10

and raise or lower extension screed until

extension screed plate is flush with main

screed plate.

c.

Repeat procedure for remaining extension

screed.

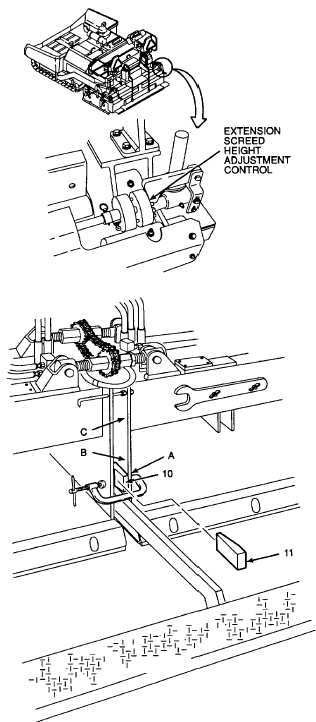

3.

CLAMP SPACER WEDGES BETWEEN MAIN

SCREED HALVES.

Screed halves are heavy and are secured

together and supported by main screed plate.

Do not remove main screed plates without

inserting spacer wedges between halves of

main

screed.

Equipment

damage

and

personnel injury may result from failure to

reinforce main screed halves.

NOTE

A total of six spacer wedges will be required

to keep the main screed halves separate.

a.

Place spacer wedge (10), with the large end

toward the front of the paving machine, in

between the two main screed halves.

Place the wedge at position A of the screed

halves.

b.

Place second spacer wedge (11), with the

thin end toward the front of the paving

machine and with the tapered edge against

spacer wedge (10).

c.

Use a hammer and drive spacer wedge

(11) against spacer wedge (10) until the

gap between the two main screed halves is

filled and maintained.

d.

Install a C-clamp across the main screed

halves, securing spacer wedges (10 and

11) in position.

e.

Repeat steps a through d, placing spacer

wedges in position B and position C of the

gap between the main screed halves.

-

GO TO NEXT PAGE

2-1024