TM 5-3895-373-20

13.7.

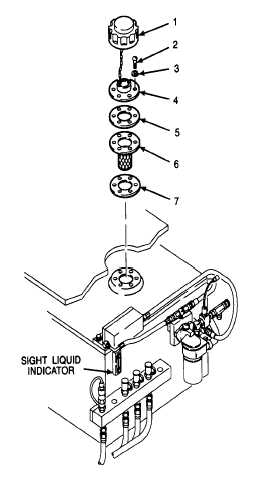

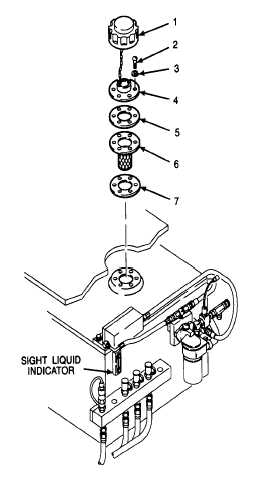

REPAIR HYDRAULIC RESERVOIR- Continued.

A.

REMOVE - Continued.

Do not allow any parts or material to

fall into hydraulic reservoir. Debris

may contaminate hydraulic oil or clog

system.

b.

Remove hydraulic reservoir cap (1).

c.

Remove machine screws (2) and lockwashers

(3). Discard lockwashers. Be sure to save

machine screws for reuse at installation of new

filler neck.

d.

Remove and discard used filler neck (4), gasket

(5), strainer (6), and gasket (7).

2.

REMOVE SIGHT LIQUID INDICATOR.

Cleaning solvent, P-D-680, is TOXIC

and flammable. Wear protective

goggles and gloves. Use only in a

well ventilated area. Avoid contact

with skin, eyes, and clothes, and do

not breathe vapors. Keep away from

heat or flame. Never smoke when

using solvent; the flashpoint for Type

m cleaning solvent is 200°F (93,3°C).

Failure to do so may result in injury

or death to personnel.

If personnel become dizzy while

using cleaning solvent, immediately

get fresh air and medical help. If

solvent contacts skin or clothes,

flush with cold water. If solvent

contacts eyes, flush eyes with water

and get immediate medical attention.

Cleanliness is extremely important

when working around an open

hydraulic system. Ensure that the

area around the sight liquid indicator

is clean and free of debris prior to

removal. Failure to do so could

contaminate the hydraulic system

and cause component damage.

a.

Clean exposed surfaces of sight liquid indicator

and surrounding area with a clean lint-free cloth

soaked in cleaning solvent. Dry area with a

clean lint-free cloth.

GO TO NEXT PAGE

13-44