TM 5-3895-373-20

C.

INSPECT.

1.

VISUALLY INSPECT BEARING SHAFTS

FOR

SCORING

OR

GOUGING

ON

BEARING

SURFACE.

REPLACE

BEARING SHAFTS IF DAMAGED.

2.

INSPECT PUSH ROLLER AND

SPHERICAL BEARINGS.

a.

Roll push roller across a flat surface and

check for bending or an out of round

shape. If roller is bent or out of round,

replace it.

b.

Check spherical bearings in ends of push

roller by rotating by hand. If bearings turn

rough or bind, replace bearing per step D.

3.

INSPECT STRAIGHT HEADED PIN

FOR CRACKS, GOUGES, DENTS, OR

NICKS. POLISH OUT ANY RAISED

METAL USING CROCUS CLOTH. IF

GAUGES OR WEAR EXCEEDS 1/8 IN.

(3.18 mm) IN DEPTH OR CRACKS ARE

FOUND, REPLACE PIN.

D.

REPAIR.

NOTE

Replace spherical bearings in push

roller only if determined necessary by

inspection step C.2.b.

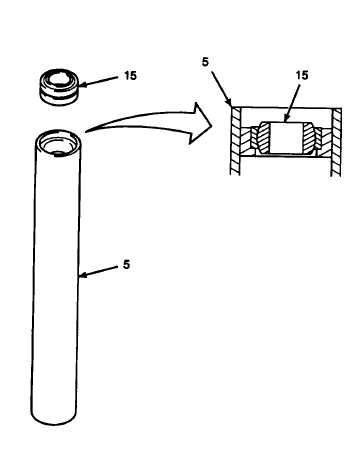

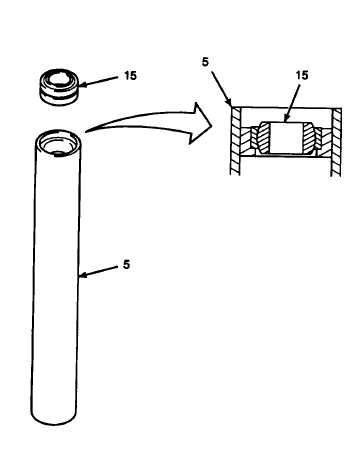

1.

REMOVE SPHERICAL BEARINGS FROM

PUSH ROLLER.

a.

Place push roller (5) into a bench vise.

b.

Pull spherical bearings (15) from push

roller (5) using universal puller kit with

internal jaws.

Cleaning solvent, PD680, is TOXIC

and flammable. Wear protective

goggles and gloves. Use only in a

well ventilated area. Avoid contact

with skin, eyes, and clothes, and do

not breathe vapors. Keep away from

heat or flame. Never smoke when

using solvent; the flashpoint for Type

m cleaning solvent is 200°F (93,30C).

Failure to do so may result in injury

or death to personnel.

If personnel become dizzy while

using cleaning solvent, immediately

get fresh air and medical help. If

solvent contacts skin or clothes,

flush with cold water. If solvent

contacts eyes, flush eyes with water

and get immediate medical attention.

c.

Clean

grease

and

paving

material

accumulation from push roller bearing

bores with a cleaning cloth soaked in

cleaning solvent.

GO TO NEXT PAGE

10-7