TM 5-3895-373-20

C.

ADJUST.

1.

CHECK FAN BELT TENSION.

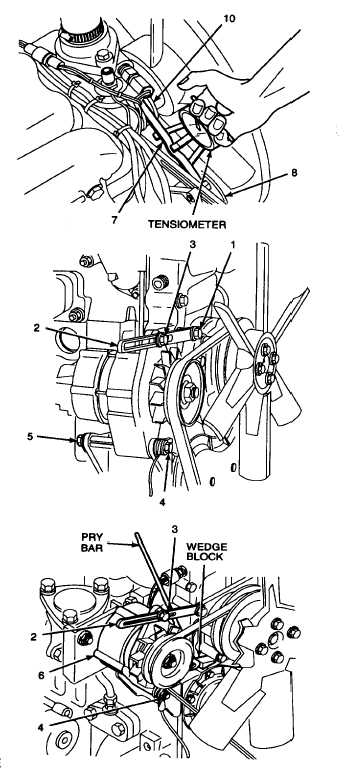

a.

Install tension meter on fan belt (7) midway

between alternator pulley (8) and water pump

pulley (10).

b.

Push down on tension meter plunger and read

dial indicator. Tension should be 10 lb (45 N)

nominal.

c.

Hold self-locking hex nut (4) and tighten pivot

bolt (5) to 20 lb-ft (27 N•m). Recheck tension on

fan belt (7). If necessary, readjust fan belt

tension per step C.2.

2.

ADJUST FAN BELT TENSION.

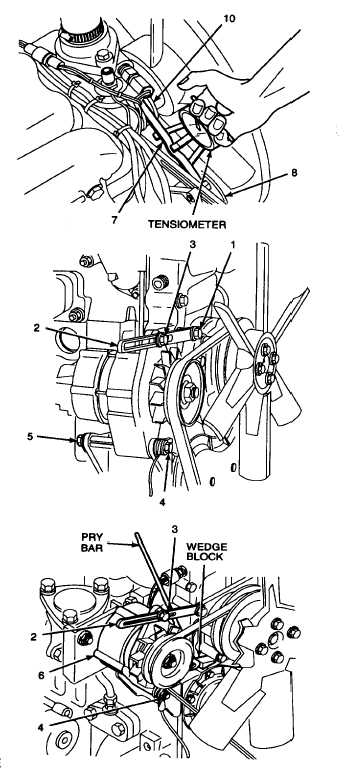

a.

Loosen adjustment screw (3), hold self-locking

hex nut (4), and loosen pivot bolt (5).

b.

Loosen hex head cap screw (1) to allow for

movement of belt adjusting arm (2).

c.

Using wedge block and pry bar, readjust position

of alternator (6). When tension feels right,

maintain pressure and tighten adjustment screw

(3) to 20 lb-ft (27 N•m).

d.

Tighten hex head cap screw (1) to 14 lb-ft (19

N•m).

e.

Check fan belt tension per step C.1.

f.

Repeat steps a through d until tension meter

indicates 10 lb (45 N).

g.

Hold self-locking hex nut (4) and tighten pivot

bolt (5) to 20 lb-ft (27 N•m). Remove pry bar and

wedge block.

NOTE

FOLLOW-ON-TASK:

Close front top left access door per TM 5-3895-373-10.

END OF TASK

6-21(6-22 blank)