TM 5-3895-373-20

B.

INSTALL - Continued.

2.

INSTALL FUEL FILTER ASSEMBLY.

Fuel is very flammable and can

explode easily.

To avoid serious injury or death:

Always wear safety glasses/goggles

at all times.

Keep fuel away from open flame or

any spark (ignition source).

Keep at least a B-C fire extinguisher

within easy reach when working with

fuel or on a fuel system.

Do not work on fuel system when

engine is hot; fuel can be ignited by a

hot engine.

Post signs that read "NO SMOKING

WITHIN 50 FEET" when working with

open fuel lines or fuel tanks.

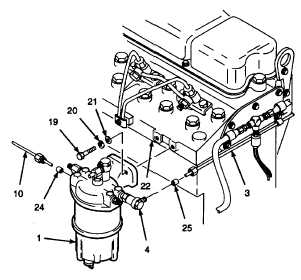

a.

Place gasket (24) onto fuel injection pump metal

tube (10). Place rubber compression sleeve (25)

onto induction heater fuel pipe (3).

Thread locking compound solvent

can cause eye damage. Wear safety

goggles/glasses when using. Avoid

contact with eyes. If solvent contacts

eyes, flush eyes with water and get

immediate medical attention.

b.

Clean hex head cap screw threads (19) with a

clean cleaning cloth soaked in thread locking

compound solvent.

Thread locking compound can cause

eye

damage.

Wear

safety

goggles/glasses when using. Avoid

contact with eyes. If compound

contacts eyes, flush eyes with water

and get immediate medical attention.

c.

Install lockwasher (20) and washer (21) onto hex

head cap screw (19). Apply thread locking

compound to cap screws.

d.

Hold fuel filter assembly (1) in position to place

metal tube (10) into fuel filter assembly and

induction heater fuel pipe (3) into multiple

connector (4) but do not tighten at this time.

e.

Secure fuel filter assembly (1) onto cylinder head

assembly (22) using hex head cap screws (19)

with

lockwashers

(20)

and

washers

(21).

Tighten cap screws to 42 Ib-ft (57 N•m).

GO TO NEXT PAGE

4-59