TM 5-3895-371-24 & P

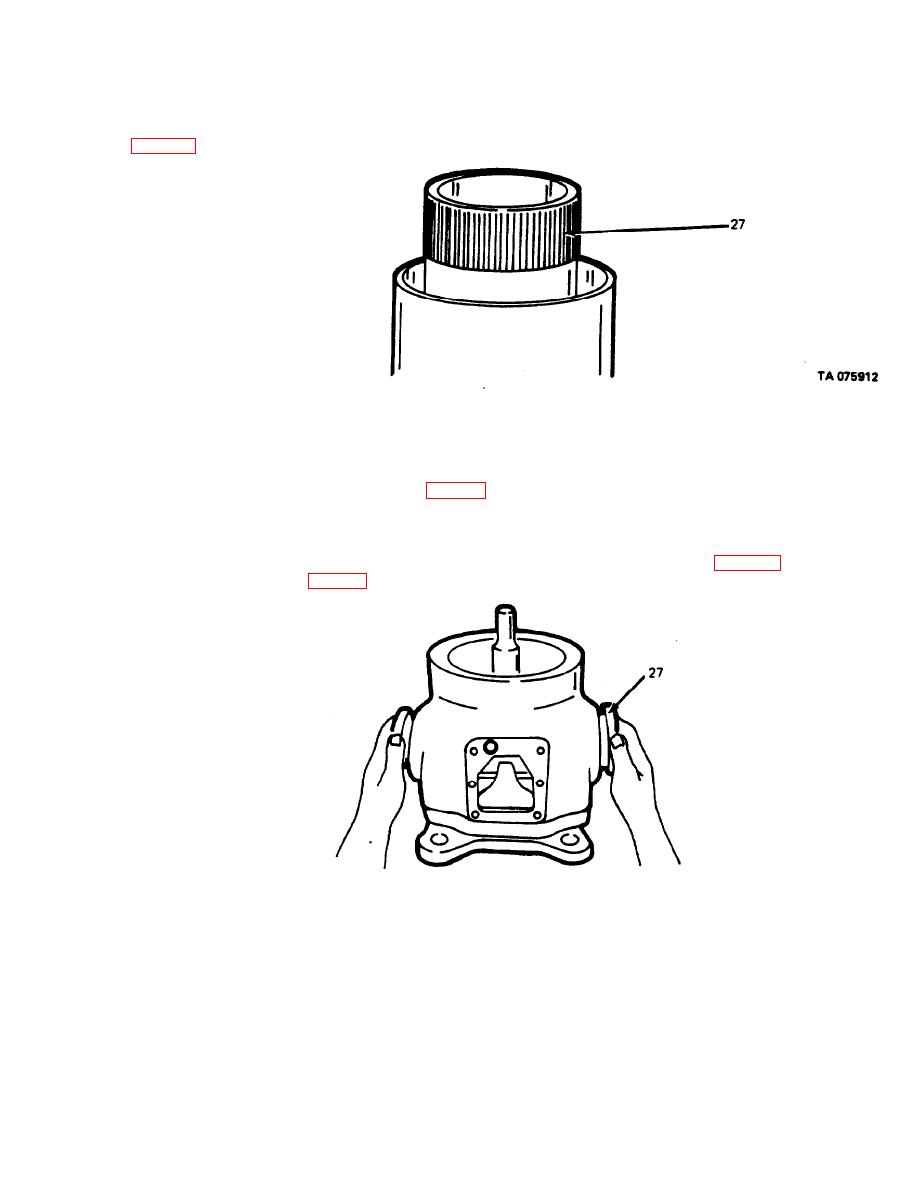

(20) Inspect the trunnions (27). Small nicks or burrs can be removed with 500 grit emery

cloth. If galling or scoring can be felt with the fingernail, the trunnion should be discarded. (Refer to

Figure 3-41. Inspecting Trunnions.

screwdriver through the cam lever opening in the housing and between the cam assembly and the back

face of the flange. A slight downward pressure on the screwdriver will lift the cam assembly into posi-

tion. If the trunnions do not slide easily into place, rotate the trunnions slowly back and forth while

repositioning the cam with the screwdriver until the trunnions seat properly. (Refer to fig. 3-42). In-

stall eight capscrews (25, fig. 3-4) and lockwashers (26) in trunnions and torque to 11 lb-ft (14.9 N-m).

Figure 3-42. Installing Trunnions.

3-37