TM 5-3895-356-14&P

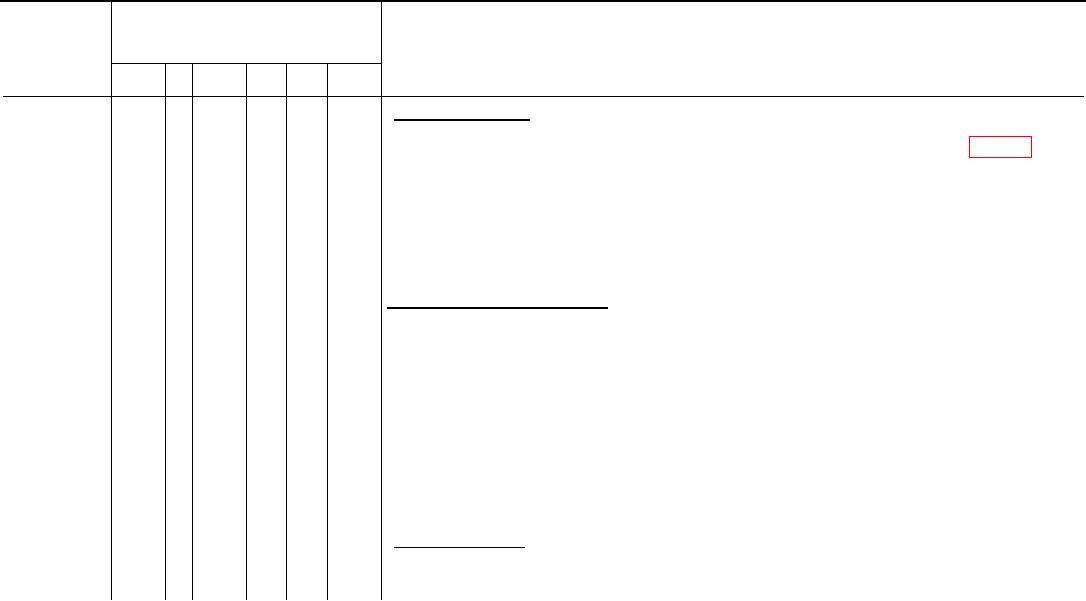

ORGANIZATIONAL PREVENTIVE MAINTENANCE CHECKS AND SERVICES

Q-QUARTERLY

S-SEMIANNUALLY

A-ANNUALLY

B-BIENNIALLY

H-HOURS

MI-MILES

ITEM TO BE INSPECTED

ITEM NO

INTERVAL

PROCEDURE: CHECK FOR AND HAVE REPAIRED, FILLED, OR ADJUSTED AS NEEDED

Q

S

A

B

H

MI

PERFORM ALL OPERATOR PMCS FIRST

Spray Bar Assembly

23

X

Check that spray bar positions itself whenever control is activated. Adjust as needed. (Page 27)

24

X

Check safety chains. Replace as necessary.

25

X

Check relation of quadrant lever position with nozzle position Adjust linkage as needed

26

X

Check spray bar linkages, bars, toggles, fulcrum lever, nozzles and swivel bearing. If damaged,

replace.

Air Control, Cables and Cylinders

27

X

Inspect air control box assembly for corrosion, air leaks, bare wires. Repair bare wires and air leaks.

Report control box malfunction to DS Maintenance.

28

X

Inspect cylinders If damaged, report to DS Maintenance

29

X

Check recording Bitumeter cable operation and service it

30

X

Check pump tachometer cable operation and service it

31

X

Check fire extinguisher for broken seal, low charge and proper mounting. If damaged or low charge

replace

General Lubrication

32

X

Quarterly perform all daily and monthly service as stated in TM 5-3895-356-14&P.

D10