TM 5-3895-356-14&P

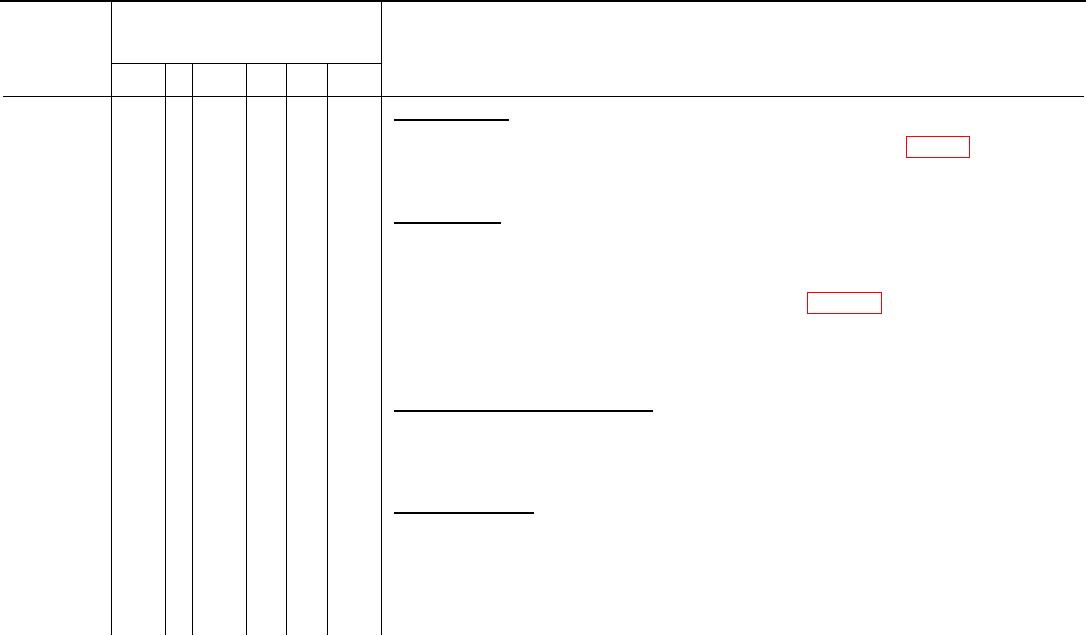

ORGANIZATIONAL PREVENTIVE MAINTENANCE CHECKS AND SERVICES

Q-QUARTERLY

S-SEMIANNUALLY

A-ANNUALLY

B-BIENNIALLY

H-HOURS

MI-MILES

ITEM TO BE INSPECTED

ITEM NO

INTERVAL

PROCEDURE: CHECK FOR AND HAVE REPAIRED, FILLED, OR ADJUSTED AS NEEDED

Q

S

A

B

H

MI

PERFORM ALL OPERATOR PMCS FIRST

Electrical System

1

X

Check wiring harness for corrosion and bare wires Replace defective wiring (Page 49).

2

X

Check all lights for proper operation Replace defective lamps and lights

Distributor Body

3

X

Check material storage tank, sub-frame, tie-down, tool box and fasteners for obvious damage, w eld

breaks, missing items. Repair or notify DS Maintenance IAW MAC.

4

X

Check that manhole cover seals properly Repair as needed. (Page 143).

5

X

Check overflow pipe. Clean any material build up from pipe

6

X

Check accessory items, bell, hand spray gun, asphalt hose and connector. Repair as needed.

Hydraulic System and Asphalt Controls

7

X

Check all hydraulic lines and fittings

If damaged, replace.

8

X

Check and service all control linkage If damaged, replace

Burner Fuel Systems

9

X

Check fuel lines and fittings If damaged, replace.

10

X

Check burner fuel tank holding straps If damaged, repair or replace.

11

X

Dram and clean burner fuel tank

D8