TM 5-3895-356-14&P

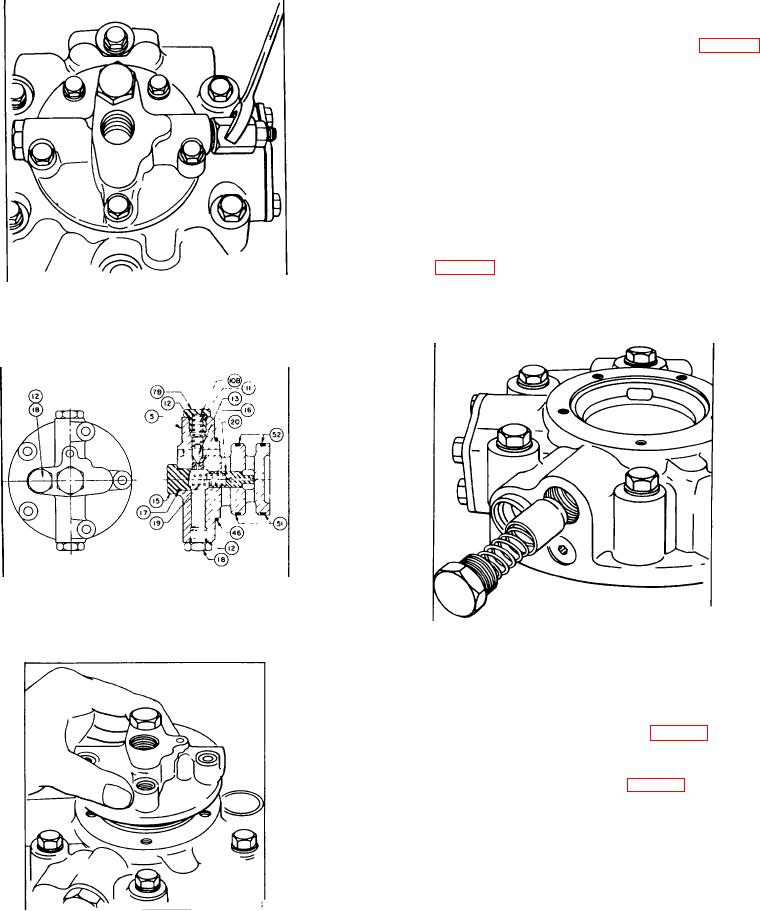

EXCEPTION

Units no longer In production may have a nonadjustable

high pressure pilot valve spring seat (7B) (See Fig 187).

Remove spring seat (7B) and shim(s) (10), O-ring (12),

spring (11), and valve pilot (13) and proceed to Step 5.

C-4 Remove Inner spring seat (10), O-ring (6), pilot

spring (11), and valve pilot (13).

C-5 Inspect pilot valve seat (16) If damaged, replace

body assembly (5) Do not attempt to remove valve seat

(16) from valve body (5).

C-6 Remove 3 hex bolts (50), 2 hex bolts (48), and 5

lock washers (47). Lift valve body (5) from motor cover

(4) See Fig 188.

C-7 Remove O-ring (46), back-up rings (51), and O-rings

Figure 186.

(52).

Removing high pressure pilot valve

Figure 187.

Phase III non-adjustable high pressure

Figure 189.

relief valve

Removing low pressure relief valve

MOTOR DISASSEMBLY

1. Remove low pressure relief valve plug (73) O-ring

(17), spring (62), and plunger (61). See Fig 189.

2. Remove shuttle valve plugs (35) and O-rings (17).

Slide shuttle (32) from cover (4) See Fig 190.

NOTE:

Spring centering shuttle plugs (29) and O-ring (17)

should be removed as an assembly Plug (28) spring

(30), and plunger (31) should not be removed from plug

(29) unless damaged. If damaged, remove plug (28)

and slide spring (30) and plunger (31) from plug (29).

3 Unless leakage is experienced, do not remove plugs

Figure 188.

(33) or O-rings (34) If leaking, replace O-rings(34).

Removing high pressure relief valve body

116