Engine Systems

Air System

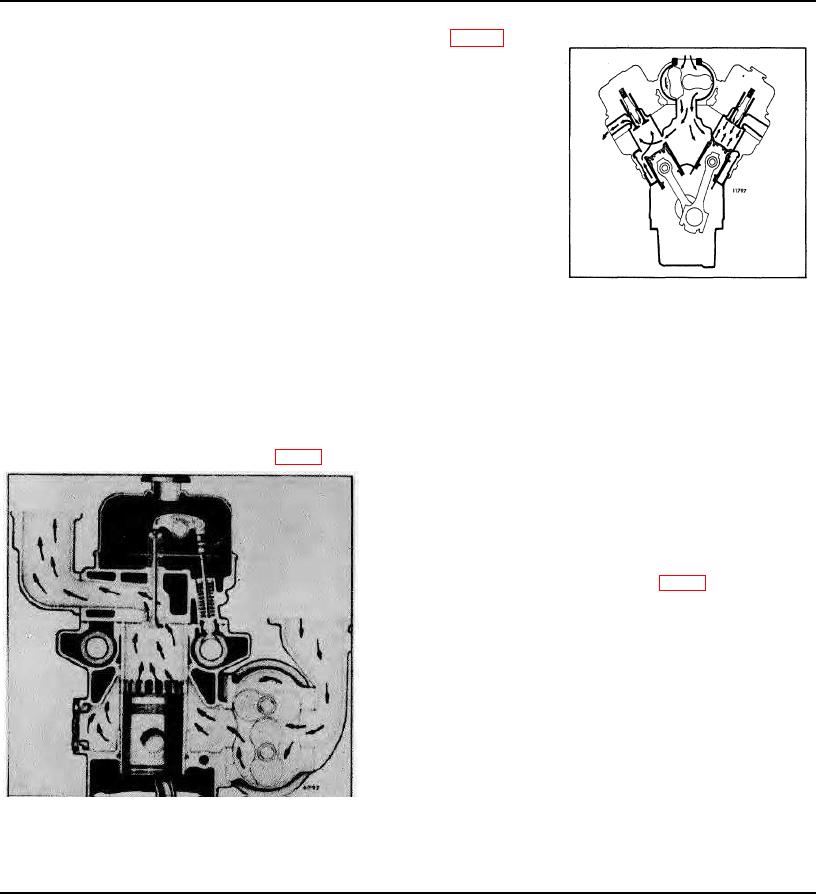

In the scavenging system used in two-cycle engines, illustrated in Figs. 6 and 7,

a charge of air is forced into the cylinders by the blower and thoroughly sweeps

out all of the burned gases through the exhaust valve ports. This air also helps to

cool the internal engine parts, particularly the exhaust valves. At the beginning of

the compression stroke, each cylinder is filled with fresh, clean air which provides

for efficient combustion.

The air, entering the blower from the air silencer or air cleaner, is picked up by the

blower rotor lobes and carried to the discharge side of the blower. The

continuous discharge of fresh air from the blower enters the air chamber of the

cylinder block and sweeps through the intake ports of the cylinder liners.

The angle of the ports in the cylinder liner creates a uniform swirling motion to the

intake air as it enters the cylinder. This motion persists throughout the

compression stroke and facilitates scavenging and combustion.

Fig. 7 - Air Intake System Through Blower and

Air Cleaners

Engine (6V-53 Engine)

Several types of air cleaners are available for use with industrial

engines. The light-duty oil bath air cleaner is used on most models.

However, a heavy-duty oil bath type or a dry type air cleaner may be installed where the engine is operating in heavy

dust concentrations.

The air cleaners are designed for fast, easy disassembly to facilitate efficient servicing. Maximum protection of the

engine against dust and other forms of air contamination is possible if the air cleaner is serviced at regular intervals.

The light-duty oil bath type air cleaner (Fig. 8) consists of a metal wool cleaning element supported inside of a housing

which contains an oil reservoir. A chamber beneath the oil

reservoir serves as a silencer for the incoming air to the blower.

Air is drawn into the cleaner by the blower and passes over the

top of the oil bath, where a major portion of the dirt is trapped,

then up through the metal wool, where the finer particles are

removed, and then down the central duct to the blower.

The heavy-duty oil bath type air cleaner (Fig. 9) consists of the

body and fixed filter assembly which filters the air and condenses

the oil from the air stream so that only dry air enters the engine.

The condensed oil is returned to the cup where the dirt settles out

of the oil and the oil is recirculated. A removable element

assembly removes a major part of the dust from the air stream

thereby decreasing the dust load to the fixed element. An inner

cup, which can be removed from the outer (oil cup), acts as a

baffle in directing the oil-laden air to the element and also

controls the amount of oil in circulation and meters the oil to the

element. The oil cup supports the inner cup and is a reservoir for

oil and a settling chamber for dirt.

Service the light-duty oil bath air cleaner as follows:

Fig. 6 - Air Intake System Through Blower

and Engine (In-line Engine)

Page 17