Engine Systems

1. Loosen the wing bolt and remove the air cleaner assembly from the air inlet

housing. The cleaner may then be separated into two sections; the upper section or

body assembly contains the filter element, the lower section consists of the oil cup,

removable inner cup or baffle and the center tube.

2. Soak the body assembly and element in fuel oil to loosen the dirt; then flush the

element with clean fuel oil and allow it to drain thoroughly.

3. Pour out the oil, separate the inner cup or baffle from the oil cup, remove the

sludge and wipe the baffle and outer cup clean.

4. Push a lint-free cloth through the center tube to remove dirt or oil.

5. Clean and check all of the gaskets and sealing surfaces to ensure air tight seals.

6. Refill the oil cup to the oil level mark only, install the baffle, and reassemble the

air cleaner.

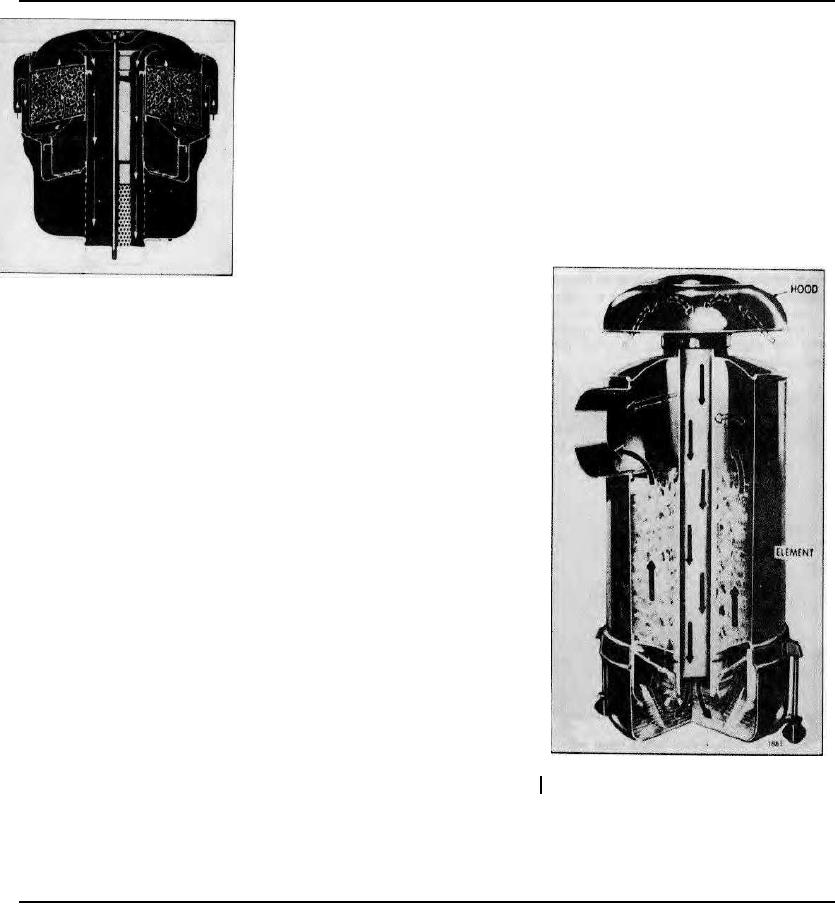

7. Check the air inlet housing before

Fig. 8 - Light Duty Oil Bath Air installing the air cleaner assembly on the

engine. The inlet will be dirty if air cleaner

Cleaner

servicing has been neglected or if dust-

laden air has been leaking past the air

cleaner or air inlet housing seals.

8. Make sure that the air cleaner is seated properly on the inlet housing and

the seal is installed correctly.

Tighten the wing bolt until the air cleaner is securely mounted.

Service the heavy-duty oil bath air cleaner as follows:

1. Loosen the wing nuts and detach the lower portion of the air cleaner

assembly.

2. Remove the detachable screen by loosening the wing nuts and rotating

the screen one-quarter turn.

One of the most important steps in properly cleaning the tray type oil bath air

cleaner is a step that is most overlooked. Unless the filter tray is thoroughly

cleaned, satisfactory performance of the engine cannot be realized. The

presence of fibrous material found in the air is often underestimated and is

the main cause of the malfunctioning-of heavy-duty air cleaners. This

material comes from plants and trees during their budding season and later

from airborne seed from the same sources. Figure 10 illustrates the severity

of lugging in a tray that is 50% plugged. The solid black areas in the mesh

are accumulations of this fibrous material. When a tray is plugged in this

manner, washing in a solvent or similar washing solution will not clean it

satisfactorily. It must be blown out with high pressure air or steam to remove

the material that accumulates between the layers of screening. When a

Fig. 9 - Heavy-Duty Oil Bath Air

Cleaner

Page 18