TM 5-3895-385-23-1

0048

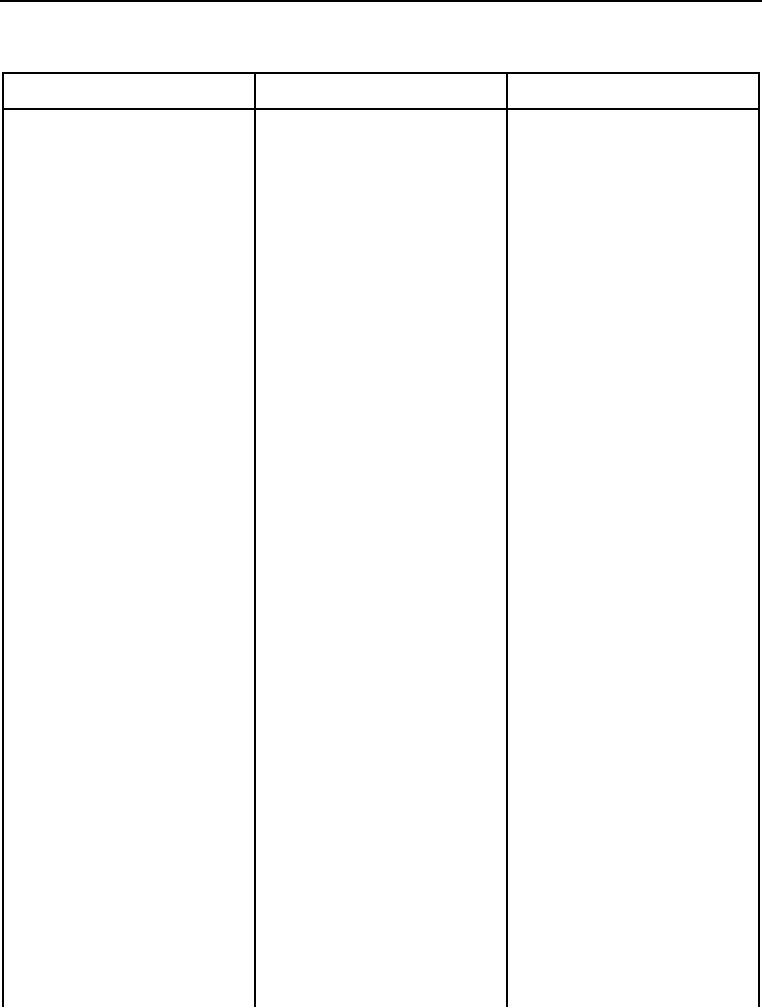

Table 1. SPN#190, FMI#2 ― Crankshaft Speed/Position Sensor Signal Lost or Degraded -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. Place a jumper wire between

the ECM wiring harness

connector W25 C12 crankshaft

speed/position sensor +5 volt

SUPPLY pin (pin 1) and the

crankshaft speed/position

sensor SIGNAL pin (pin 3) (WP

0448, Vol 3, Figure 23).

4. Start engine (TM 5-3895-385-

10), and let idle for 1 minute.

5. Check active engine faults

1. If fault code SPN#190, FMI#2 is

screen for fault code SPN#190,

displayed, turn keyless engine

FMI#2.

switch to the OFF position (TM

5-3895-385-10), and proceed to

next malfunction.

2. If fault code SPN#190, FMI#2 is

not displayed, turn keyless

engine switch to the OFF

position (TM 5-3895-385-10),

and proceed to malfunction 5.

4. Crankshaft speed/position

1. Remove the crankshaft

sensor damaged.

speed/position sensor from the

engine (WP 0333, Vol 2).

2. Inspect the crankshaft

1. If damaged, replace crankshaft

speed/position sensor for

speed/position sensor (WP

damage.

0333, Vol 2).

2. If not damaged, proceed to next

test.

3. Inspect the crankshaft pulley for

1. If damaged, replace the

damage or spinning (WP 0324,

crankshaft pulley (WP 0324,

Vol 2).

Vol 2).

2. If not damaged, reinstall

crankshaft speed/position

sensor (WP 0333, Vol 2), and

proceed to next malfunction.

5. Engine ECM wiring harness,

1. Inspect engine ECM wiring

1. If damaged, replace engine

connector, or connector pins

harness connector W25 C12 for

ECM wiring harness (WP 0334,

damaged.

damage or loose pins.

Vol 2).

2. If not damaged, proceed to next

test.

0048-3