TM 5-3895-385-23-1

0048

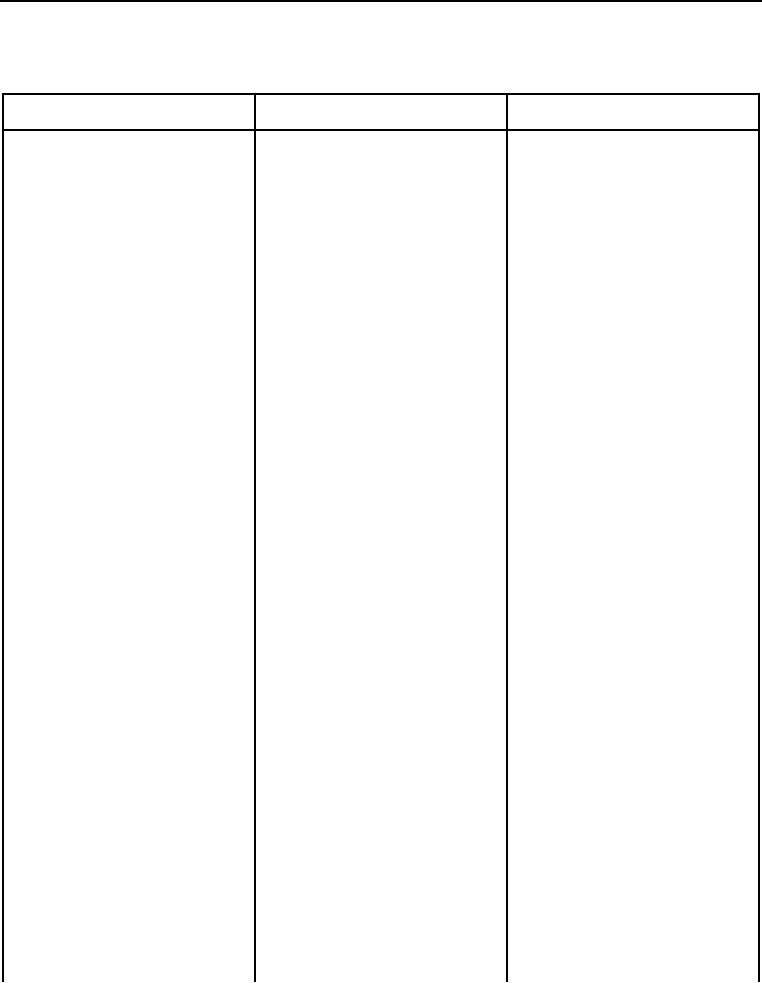

Table 1. SPN#190, FMI#2 ― Crankshaft Speed/Position Sensor Signal Lost or Degraded -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

5. Check active engine faults

1. If fault code SPN#1043, FMI#4

screen for fault code

is displayed, turn keyless

SPN#1043, FMI#4.

engine switch to the OFF

position (TM 5-3895-385-10),

and proceed to SPN#1043,

FMI#4 troubleshooting

procedure.

2. If fault code SPN#1043, FMI#4

is not displayed, turn keyless

engine switch to the OFF

position (TM 5-3895-385-10),

and proceed to next

malfunction.

2. Crankshaft speed/position

1. Disconnect engine ECM wiring

sensor fault.

harness connector W25 C12

from crankshaft speed/position

sensor (WP 0451, Vol 3, Figure

46).

2. Inspect speed/position sensor

1. If damaged, replace crankshaft

for damage or loose connector

speed/position sensor (WP

pins.

0333, Vol 2).

2. If not damaged, proceed to next

malfunction.

3. Crankshaft speed/position

1. Turn keyless engine switch to

sensor supply voltage is

the AUX position (TM 5-3895-

incorrect.

385-10), but do not start

engine.

2. Measure voltage at ECM wiring

1. If supply voltage is between

harness connector W25 C12.

4.75 and 5.25 Volts Direct

Crankshaft speed/position

Current (VDC), turn keyless

sensor +5 volt SUPPLY pin (pin

engine switch to the OFF

1) to crankshaft speed/position

position (TM 5-3895-385-10),

sensor RETURN pin (pin 2)

and proceed to next test.

(WP 0443, Vol 3 and WP 0448,

Vol 3, Figure 23).

2. If supply voltage is not between

4.75 and 5.25 VDC, turn

keyless engine switch to the

OFF position (TM 5-3895-385-

10), and proceed to next

malfunction.

0048-2