TM 5-3895-385-23-1

0034

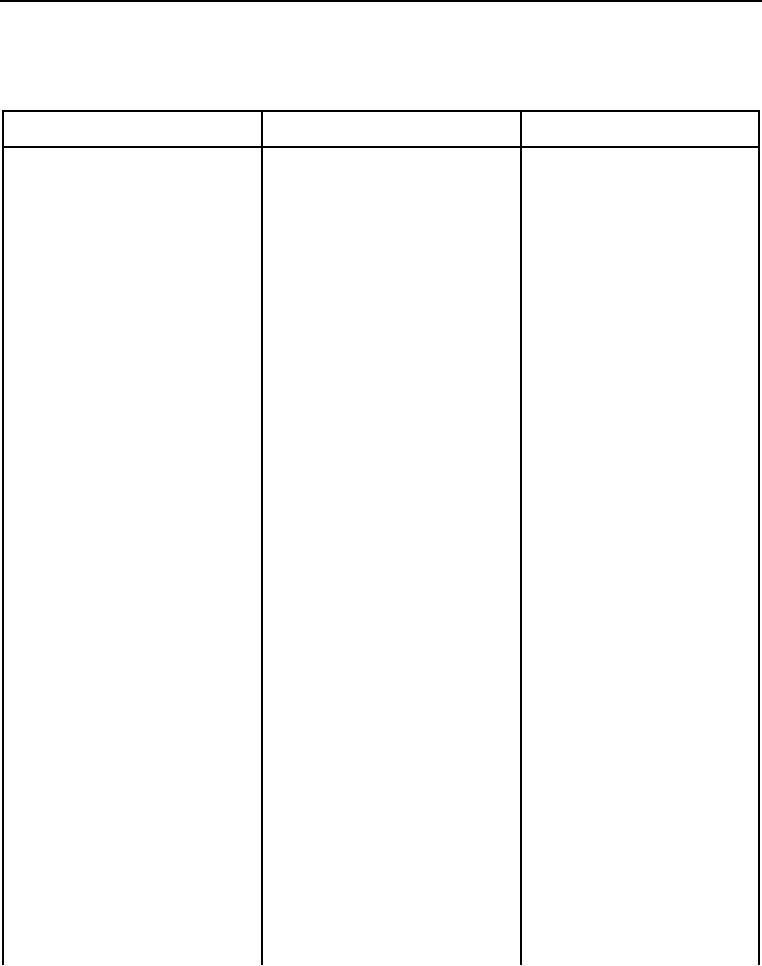

Table 1. SPN#177, FMI#0 ― Sensed Rail Fuel Pressure Exceeds

Rail Relief Valve Opening Pressure -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. If not damaged, proceed to

next malfunction.

3. Fuel pressure sensor signal wire

1. Disconnect engine ECM wiring

or connector pins damaged.

harness connector W25 C1 from

ECM (WP 0451, Vol 3, Figure

45).

2. Inspect ECM and ECM pins for

1. If damaged, replace engine

damage.

ECM (WP 0332, Vol 2).

2. If not damaged, restore

equipment to original

condition, and proceed to

next malfunction.

4. Restricted fuel drain line.

1. Disconnect the fuel drain line

connecting the fuel pump drain

to the fuel return manifold (WP

0448, Vol 3, Figure 54).

2. Attach pressure gauge and

adapter at the high-pressure fuel

pump drain manifold (WP 0448,

Vol 3, Figure 49).

3. Start engine (TM 5-3895-385-10)

1. If fuel pressure is more than

and run at idle. Measure the fuel

2.7 pounds per square inch

return drain line pressure.

(psi) (18.6 kiloPascals (kPa)),

turn keyless engine switch to

OFF (TM 5-3895-385-10),

restore equipment to original

condition, and proceed to

next malfunction.

2. If fuel pressure is less than

2.7 psi (18.6 kPa), turn

keyless engine switch to OFF

(TM 5-3895-385-10), and

replace fuel pump actuator

(WP 0330, Vol 2).

5. Fuel pump actuator and harness

1. Disconnect engine ECM wiring

connector pins damaged.

harness connector W25 C9 from

fuel pump actuator (WP 0451,

Vol 3, Figure 46).

0034-3