TM 5-3895-385-23-1

0003

TECHNICAL PRINCIPLES OF OPERATION

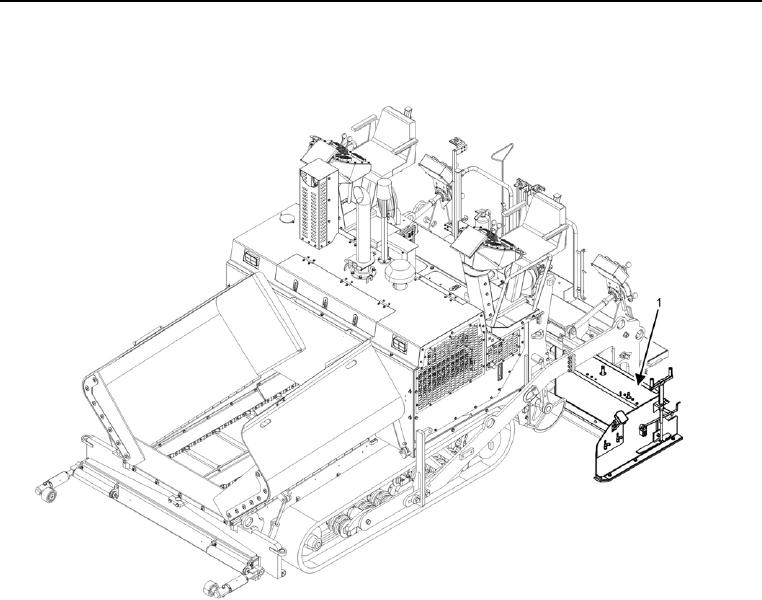

Screed

Figure 1. BMPM Screed -- Left Side (Extended).

The BMPM contains an electrically-heated floating screed (Figure 1, Item 1) that is a self-contained, attachable

unit incorporating hydraulics for raising and lowering the unit and an electric heating system powered by an on-

board generator.

The screed has two 45-inch (in) (1.14-m) hydraulically-operated screed extensions, which, when deployed, allow

paving a strip of paving material up to 15.5 ft (4.7 m) in width and up to 8 in (203-millimeters (mm)) in depth. It is

equipped with a variable crown system that can create crowns and valleys on the paving material being

distributed.

Four hydraulic-mechanical activated vibrators operate at 500 3,500 Vibrations Per Minute (VPM) each and can

compact paving material to an 8-in (0.2-m) depth. Normal compaction density yields 88 90% as measured

directly behind the screed. The vibrator motors are located on each side of the main screed unit. The screed can

be raised, lowered, and locked in the raised position for travel and is delivered with an anti-skid operator platform

containing ergonomically-designed and -located controls for paving thickness, crowning, slope, and grade.