TM 5-3895-373-34

2.38.

REPLACE/REPAIR TRACK TENSIONING RELIEF VALVE AND UNLOADING VALVE - Continued

D.

INSPECT.

1.

INSPECT TRACK TENSIONING RELIEF VALVE.

a.

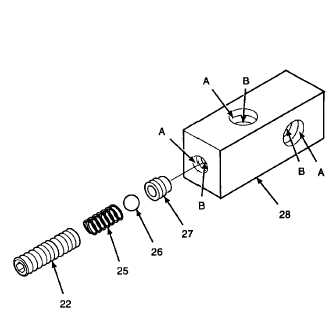

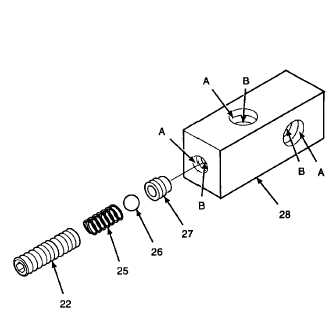

Visually inspect valve body (28), surfaces A, for

stripped threads. Use a strong light and

inspect inner bores B for foreign material.

Cleaning solvent, P-D-680, is TOXIC

and

flammable.

Wear

protective

goggles and gloves. Use only in a well

ventilated area. Avoid contact with skin,

eyes, and clothes, and do not breathe

vapors. Keep away from heat or flame.

Never smoke when using solvent; the

flashpoint for Type m cleaning solvent is

200°F (93,30C). Failure to do so may

result in injury or death to personnel.

If personnel become dizzy while using

cleaning solvent, immediately get fresh

air and medical help. If solvent contacts

skin or clothes, flush with cold water. If

solvent contacts eyes, flush eyes with

water and get immediate medical

attention.

b.

Flush valve body (28) with cleaning solvent to

remove any foreign material present. Use a

culture swab to remove foreign material from

valve body inner bore. If foreign material

cannot be removed, replace valve body.

c.

Replace valve body (28) if threads are stripped.

d.

Inspect spring (25) for distortion. Replace

spring if distortion is detected.

e.

Inspect check ball (26) and valve seat (27) for

nicks, dents, or excessive wear. Replace

check ball and valve seat if damaged.

f.

Inspect adjusting screw (22) for stripped

threads. Replace adjusting screw if threads

are damaged.

GO TO NEXT PAGE

2-526