TM 5-3895-373-34

B.

DISASSEMBLE - Continued.

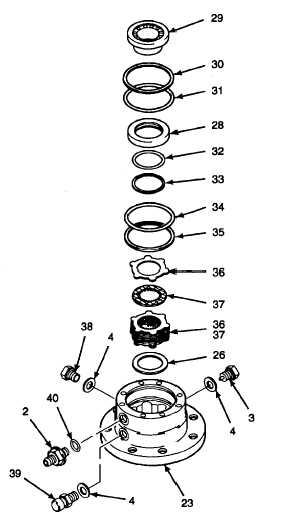

h.

Set brake housing (23) on work surface,

large flange down.

Compressed air used for cleaning purposes

will not exceed 30 psi (207 kPa). Use only

with effective chip guarding and personal

protective equipment (goggles/face shield,

gloves,

etc.).

Failure

to

take

proper

precautions may result in severe injury or

loss of vision.

NOTE

Ring spacer (28) and cylindrical piston (29)

have a close sliding fit in brake housing (23).

Ring spacer has a close sliding fit on

cylindrical piston.

i.

Direct compressed air into straight adapter

(2) to force cylindrical piston (29) from

brake housing (23). Remove cylindrical

piston.

Use caution when removing seals and o-

rings. Scratched or dented seal grooves can

cause bypass leakage. Do not use excessive

force when removing seals and o-rings. Use

an o-ring tool to remove seals and o-rings.

j.

Use an o-ring tool to remove plain seal (30)

and o-ring (31). Discard plain seal and o-

ring.

k.

Using an o-ring tool, gently pry ring spacer

(28) loose inside brake housing (23).

Remove ring spacer.

I.

Use o-ring tool to remove o-ring (32) and

plain seal (33) from ring spacer (28).

Discard o-ring and plain seal.

NOTE

Plain seal (35) may not be used in all

applications.

m.

Use an o-ring tool to remove o-ring (34) and

plain seal (35) from brake housing (23).

Discard o-ring and plain seal.

n.

Remove steel disc brakes (36), sintered

disc brake shoes (37), and thrust bearing

(26) from brake housing (23).

o.

Remove plug (3), liquid sight indicator (38),

breather

(39),

straight

adapter

(2),

preformed packing (40), and seal rings (4).

Discard preformed packing and seal rings.

GO TO NEXT PAGE

2-475