TM 5-3895-373-34

E.

INSTALL.

1.

INSTALL PISTON OIL PUMP JETS AND ALIGN

IN ENGINE BLOCK.

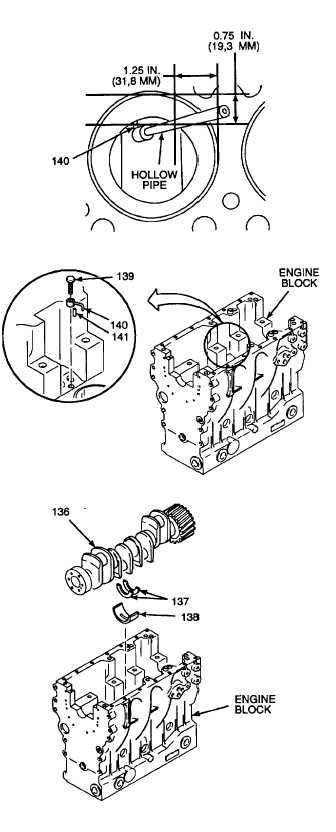

a.

Turn engine block over so bottom of engine

block is facing up.

b.

Use a pair of pliers to install dowel pins

(141).

c.

Install piston oil pump jets (140), aligning

hole in bottom of oil pump jet with dowel

pin.

d.

Install pressure relief valve (139). Tighten

valve hand tight.

e.

Insert a hollow pipe over end of piston oil

pump jet (140). Hollow pipe must project

over the top of the cylinder bore on the

engine block.

f.

Adjust angle of hollow pipe to a point 0.75

in. (19,3 mm) from fuel injection pump side

of the bore to and 1.25 in. (31,8 mm) from

the engine front side of the bore.

g.

While

holding

hollow

pipe

in

correct

position, tighten pressure relief valve (139)

to 20 lb-ft (27 N•m).

2.

INSTALL MAIN SLEEVE BEARINGS, MAIN

BEARING CAPS, CRANKSHAFT ASSEMBLY,

REAR FILLER BLOCK, CRANKSHAFT SEAL,

AND CRANKSHAFT SEAL HOUSING INTO

ENGINE BLOCK.

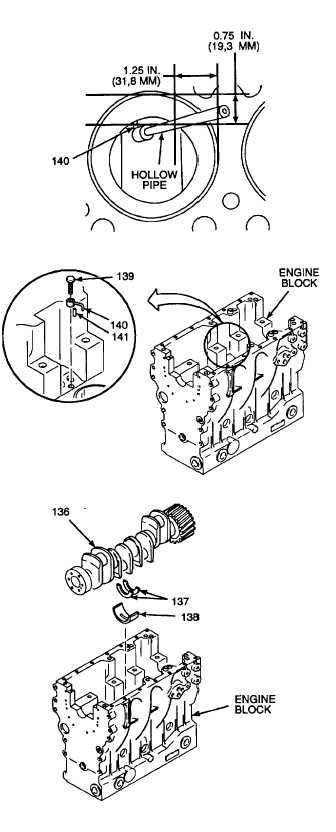

a.

Lubricate main sleeve bearings (138) with

engine oil.

b.

Install main sleeve bearings (138) on

engine block.

Crankshaft assembly is machined to

precise tolerances. Do not bump

crankshaft assembly against engine

block

when

installing

crankshaft

assembly into engine block. Damage

to crankshaft assembly may result

from careless handling.

c.

Install crankshaft assembly (136) into

engine block.

d.

Lubricate thrust washer bearings (137) with

engine oil.

e.

Install thrust washer bearings (137), with

bronze side facing outward.

GO TO NEXT PAGE

2-209