TM 5-3895-373-34

2.17

DIESEL ENGINE REPAIR - Continued.

D.

REPAIR - Continued.

Use caution when handling hot spur

gear. Severe burns may result if

caution is not used when handling

heated spur gear. Use a suitable tool

and wear insulated gloves when

handling heated spur gear.

e.

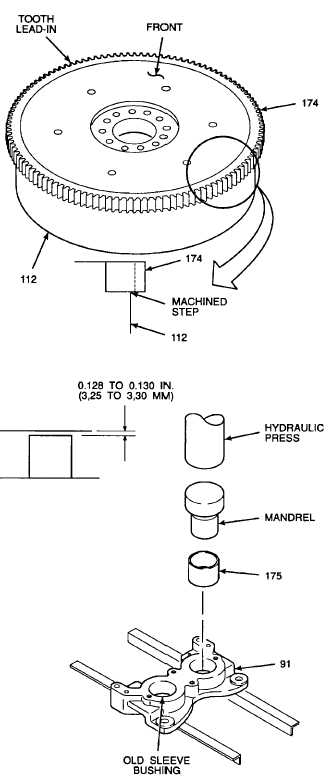

Place heated spur gear (174) on flywheel

(112) with lead-in on teeth facing front of

flywheel. Ensure spur gear is fully seated

against machined step on flywheel.

f.

Allow flywheel and spur gear to cool to

room temperature before handling.

6.

REPAIR BALANCER UNIT BY REPLACEMENT

OF

SLEEVE

BUSHINGS

AND

NEEDLE

BEARINGS.

a.

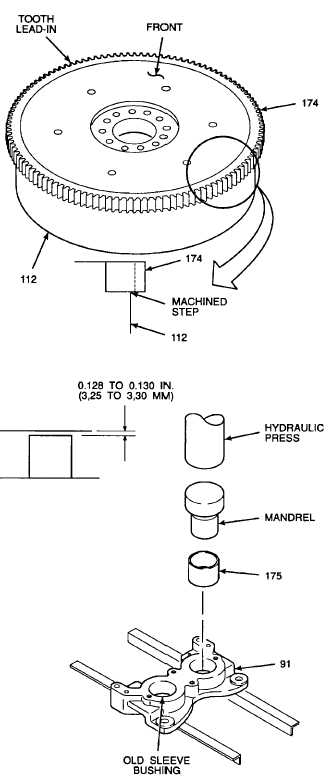

Place balancer unit frame end (91) on a

hydraulic press frame.

b.

Use a mandrel (Item 11, Appendix C) to

press new sleeve bushings (175) into

balancer unit frame end (91), at the same

time pressing out old sleeve bushings.

Discard old sleeve bushings.

c.

Sleeve bushings (175) must be 0.128 to

0.130

in.

(3,25

to

3,30

mm)

below

machined face of balancer unit frame end

when installed.

GO TO NEXT PAGE

2-192